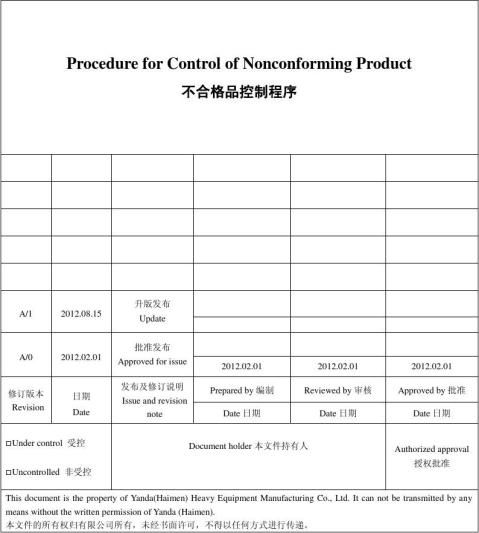

Procedure for Control of Nonconforming Product 不合格品控制程序-A1

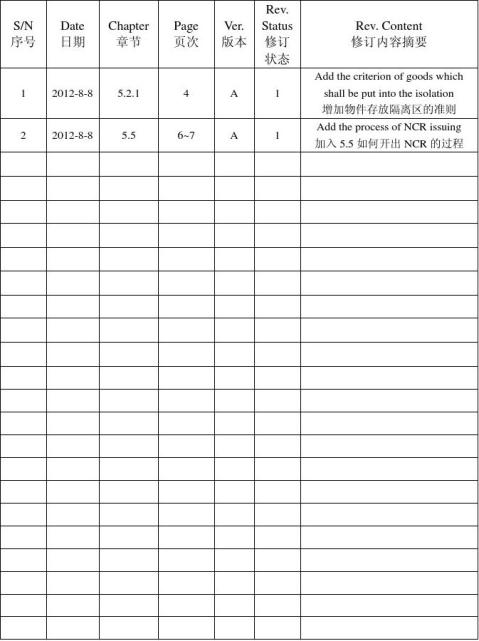

Revision History文件修订记录

1. Purpose目的

To ensure that substandard products are identified and controlled to prevent unintended use or delivery of nonconforming product

确保不合格的产品得到标识和控制,防止不合格品的非预期使用或交付。

2. Scope范围

Applies in the control and management in purchase, manufacture, installation and maintenance, or after delivery to find nonconforming product.

适用于在进货、制造、安装和维修过程或交付后发现不合格品时的控制和管理。

3. Definitions定义

None无

4. Responsibilities职责

4.1. The production sector, the warehouse is responsible for identification and isolation of the nonconforming product.

生产部门、仓库负责对不合格品进行标识和隔离。

4.2. The production sector is responsible for nonconforming product disposal

found in team self-test and mutual inspection.

生产部门负责对班组自检、互检中发现不合格品进行处置。

4.3. QHSE responsible for product identification, labeling and re-examination in inspection / testing of the nonconforming, and the establishment of a substandard product information Ledge.

QHSE部负责对检验/试验中对不合格品进行识别、标识和复检,建立不合格品信息台账。

4.4. The Purchasing Department is responsible for the disposal of the purchase of nonconforming product (return, exchange, etc.)

物资部负责对采购不合格品的处置(退货、调换等)。

5. Procedures工作程序

5.1 Nonconforming Product Incoming Inspection Control

5.1. 进货检验的不合格品控制

5.1.1 For incoming inspection or verification of nonconforming product, the warehouse keeper should put nonconforming product isolated in the District of return / non-conforming product areas, listing identifies and register.

对进货检验或验证中发现的不合格品,仓管员把不合格品隔离存放于退货区/不合格品区,挂牌标识并进行登记。

5.1.2. QHSE organizes procurement, production, technology and personnel by meetings or documents countersigned to record the non-conforming product review and dispose. Disposal methods include returns, exchanges, and so on.

QHSE部组织采购、生产、技术等人员以会议或文件会签形式,对不合格品进行评审和处置并作好记录。处置方式有退货、调换等。

5.2 Nonconforming product control in process (process) inspection and final inspection of (finished)

过程(工序)检验和最终(成品)检验的不合格品控制。

5.2.1. The non-conforming product in process inspection and final inspection should be stored identity.Small product shall be put into the isolation, there shall be warning line and marking on the module if the module is too big to move it to the isolation.

过程检验和最终检验后的不合格品应进行标识。小件产品存放在隔离区;大件物体不能放入隔离区的,应用警示带进行标识,并贴上标签.

5.2.2 A single (item) or a small number of rejected parts found in the production process, production department is responsible for disposal.

生产过程中发现单个(项)或少量不合格零件时,由生产部门负责进行处置。

5.2.3. When the quantities of non-conforming product or the number of nonconforming product exceeds the internal control indicators, QHSE Department organizes production, technology and personnel to review and disposal the nonconforming product and makes a

record, if necessary, may apply to suspend production. Review disposed of conclusions approved by the leadership of the department.

当出现批量不合格品或不合格品数量超过内控指标时,由QHSE部组织生产、技术等人员对不合格品进行评审和处置,并做好记录,必要时可申请暂停生产。评审处置结论需经部门主管领导批准。

5.2.4 The disposal of non-conforming product have corrective, concessions, and scrap-conforming product, corrective measures include rework and repair.

对不合格品的处置方式有纠正、让步、和报废等,不合格品的纠正有返工和返修等。

5.2.5 Rework, repair products need to re-inspection or verification to confirm the compliance of the product requirements or to meet the expected requirements.

返工、返修后的产品需再次检验或验证,以证实该产品符合规定的要求或满足预期的使用要求。

5.2.6 If reworked product quality fails to meet requirements need to make a concession which needs the consent of the authorized officer or customer approval before it is accepted.

返工后产品质量达不到要求的产品进行让步接收,产品让步接收前,需征得有关授权人员或顾客批准。

5.2.7 When product in obsolescence, Production Department is responsible for arranging non-conforming product to a scrap area, and hung up the clearly marked.

产品报废时,由生产部门负责将不合格品移至废品区,并挂上明显标识。

5.3. Customerrelatednon-conforming product control: for products have been delivered to the customer and found emergence of non-conforming will treat as product quality accidents. When receive customer complaints should carefully recorded, and in consultation with the customer about the solution (maintenance, reparations, etc.), the QHSE Department organize production department, business department, technical department to review and to meet the legitimate demands of the customer.

与顾客有关的不合格品控制:对于已经交付给客户的产品,出现不合格品时,本公司按

产品质量事故对待。在接获客户投诉时要认真记录,并与顾客协商处理办法(维修、赔款等),由QHSE部组织生产部、经营部、技术部等进行评审处置,满足顾客的正当要求。

5.4. The QHSE Department is responsible for collecting information of nonconforming product, and passed to the relevant departments, to develop corrective and preventive actions. QHSE部负责收集不合格品信息,开出NCR并传递给有关部门,以制定纠正和预防措施。

5.5 When and how to issue NCR

开NCR的条件和流程

5.5.1 NCR needs to be issued in the following situation:

以下情况下需开出NCR

a. Related to the management system涉及到管理体系

b. There has be property loss happened造成重大财产损失的

c. There is batch problem in the process工序出现批量问题

Please follow 5.5.2 in other situation其他情况参照5.5.2

5.5.2 It is not necessary to issue NCR if the problem can be solved and take some preventive actionwithin one day, if not, NCR needs to be issued.

发现问题后,若当天责任部门可以解决并能采取有效预防措施,无需开出NCR; 若当天责任部门无法解决,需开出NCR.

5.5.3 NCR process NCR流程

The inspector organize the assessment with the responsible department and related on the site when find the problem. Handle it according to the above.

质检员发现问题后,与责任部门进行沟通协调,组织相关部门人员进行现场评审。按上述规定处理。

NCR process as followed (finished on OA) NCR流程如下(OA完成):

a. The inspector start NCR, describe it as the form requirement.

b. After that, the responsible department analysis the reason, transfer it to the professional

engineer to prepare the corrective and preventive action. (E.g.: Problem about painting has been found, the corrective and preventive action shall be prepared by the painting engineer.)

c. The responsible department correct the situation according to the solution, notice the

inspector when finished. Close the NCR after confirmation by the inspector, review by the leader.

d. NCR can not be closed if the corrective action is not been finished, continue to correct;

There will be a new assessment if the corrective and preventive do not eliminate the errors.

a. 质检员发起NCR,按表单项目进行描述。

b. 发送至责任部门,待责任部门分析原因后,转至专业工程师进行纠正与预防措施的

编写。(如检查到油漆出问题,纠正与预防措施由防腐工程师来编写)。

c. 责任部门按专业工程师的意见整改完成后,通知质检员进行有效性验证。质检员确

认无误,经主管审核后关闭NCR。

e. 若责任部门未整改到位的,不予关闭,继续整改;若严格按纠正措施整改后,仍不

能消除的,重新组织评审并修改纠正与预防措施。

6. Related Documents相关文件

《Procedure for Corrective and Preventive Action 纠正和预防措施控制程序》

7. Records记录

YDHM-RE-030-001 Nonconforming Item Disposal List不合格品处理单

第二篇:不合格品控制程序

不合格品控制程序

QCX-B-XX

1 目的和适用范围

对不合格品进行控制, 是为了防止不合格品的非预期使用和交付。

本程序适用于电梯整机及配套件、加工件的采购、生产和使用运作过程中的不合格品控制。 2 职责

2.1 质检部负责组织实施不合格品控制。

2.2 技安部、经营部、材料部、工程部、维修部等部门配合实施不合格品控制。 3 工作程序

3.1 采购产品不合格品控制

3.1.1质检部质检员应按《监视和测量控制程序》中3.1的规定,负责对采购产品进行检验。

3.1.2 经检验不合格的整梯、电梯配套件、电气元器件、标准件,由质检员通知采购员作好标识,隔离存放。

3.1.3质检员将其不合格状况填入《不合格品处置单》,交质检部和总工程师分别评审,评审的结果一般是:拒收或作它用。

a) 电梯配件、电气元件的不合格采购品应做拒收处理。

b) 原材料、标准件的不合格采购产品可做他用。

3.1.5 总工程师和质检部评审后,其负责人在《不合格品处置单》中签署意见。

3.1.6 质检员根据评审意见,通知有关单位进行处置,并将处置结果填入《不合格品处置单》。 a) 拒收的不合格采购产品,由材料部或经营部退货。

b) 不合格的采购产品由材料部或经营部向供方索赔,隔离存放。

3.2 电梯安装、大修改造、维修保养过程及最终不合格品的控制

3.2.1 质检部应按《监视和测量控制程序》中的规定,对电梯安装调试、大修改造、维修保养过程及最终进行全面监视和测量。

3.2.2 在电梯安装调试、大修改造、维修保养过程中及最终出现的不合格品应由质检员通知工程部、维修部的有关人员复检核实,并将不合格情况填入《不合格品处置单》。对于严重或反复出现的不合格,报公司办公室按《纠正措施控制程序》或《预防措施控制程序》处理。

3.2.3 不合格品的处置由质检部提出意见,如质检部不能判定时由总工程师进行评审并将评审意见填写在《不合格品处置单》的相应栏目中。

3.2.4 评审和处置结果可能是:a)返工 b)返修

3.2.5 如责任单位对评审结果有异议, 责任单位可提出申请意见并填写在《不合格品处置单》的相应栏目中, 由总经理裁决。

3.2.6 质检员依据处置及裁决结果下达《电梯检查存在问题通知单》通知有关部门和人员执行后填写《电梯整改回执单》。

3.3 对在交付或开始使用后发现的不合格品,由经营部、质检部及时处理,并将有关信息报告公司办公室,采取与不合格的影响或潜在影响的程度相适应的纠正措施。

3.4 记录和保存

质检部负责《不合格品处置单》的整理和保存,按月汇总报公司办公室存档。 1 有关文件和记录

《不合格品处置单》

《电梯检查存在问题通知单》

《整改回执单》

-

self-introduction 大全

HottopicSelfintroductionVolunteerwanted招募自愿者foranInternationalEng…

-

Self-introduction

UnitThreeSelfintroductionPartIHowtoWriteSelfintroduction1BriefInt…

-

Self Introduction例文

SelfIntroductionHelloeveryoneImverygladtointroducemyselftoyouMynameisYangYi…

-

My Self-introduction

MySelfintroductionGoodmorningafternooneveryteacherandprofessorsThankyouvery…

-

self-introduction 自我介绍范文

FirstIwannasaythatallofusmusthavemadeorlistenedhundredsofthesocalledselfint…

-

不合格产品的控制程序

不合格产品的控制程序产品质量是企业生存的保证企业想要发展壮大就必须视产品质量为企业的生命所以我们一定要坚决拒绝不和格产品的出厂并努…