8D报告摸板(汽车件)

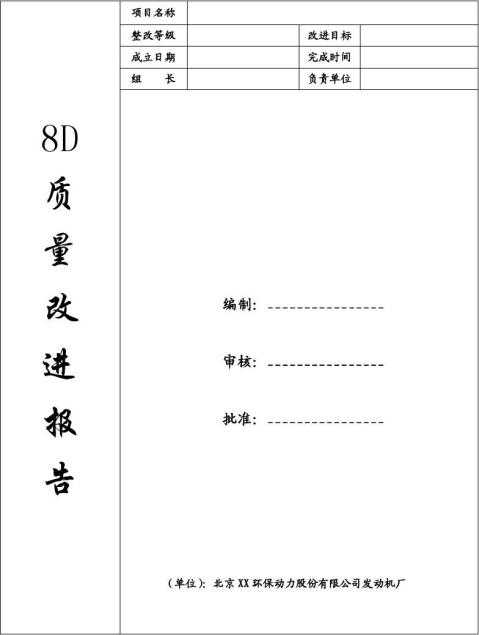

8D质量改进报告 编号:8D-05-01 北京XX动力

8D质量改进报告 编号:8D-05-01

北京·XX动力

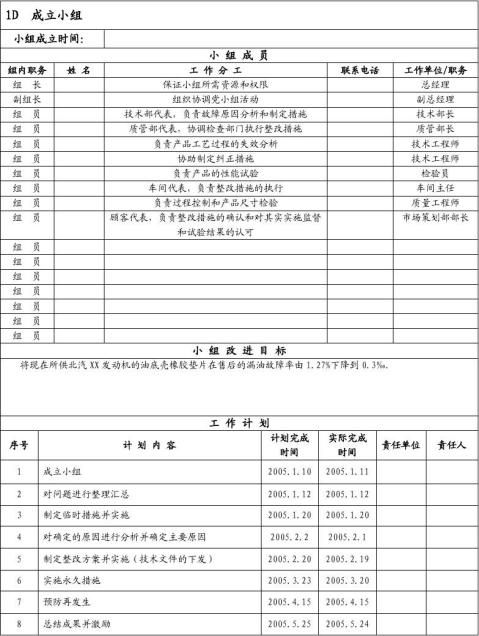

8D质量改进报告 编号:8D-05-01

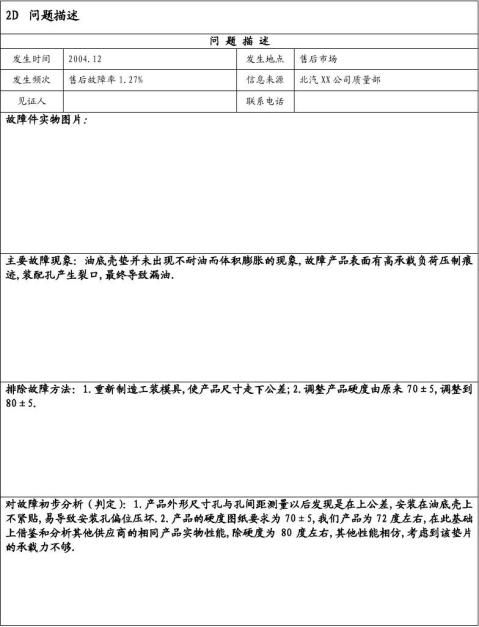

8D质量改进报告 编号:8D-05-01

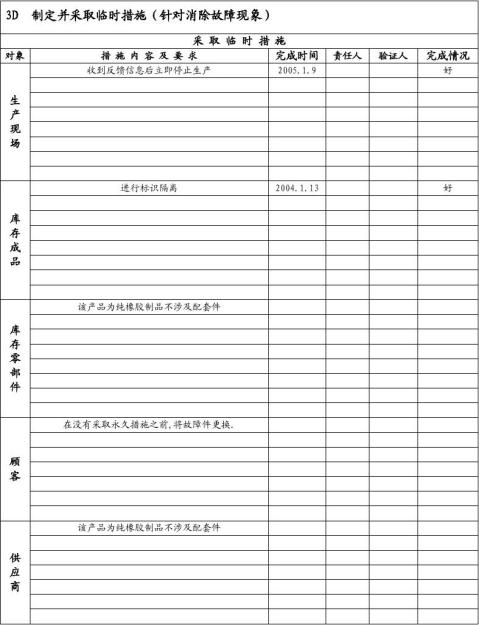

8D质量改进报告 编号:8D-05-01

8D质量改进报告 编号:8D-05-01

北京·XX动力

8D质量改进报告 编号:8D-05-01

北京·XX动力

8D质量改进报告 编号:8D-05-01

8D质量改进报告 编号:8D-05-01

8D质量改进报告 编号:8D-05-01 第 10 页 共 10 页

第二篇:8D报告范例

8D报告范例

8-Disciplines (8-D)

Corrective or Preventive Action Report & d6 ~6 S1 k4 S0 6 [+ C' h q' E2 a#

To: David Beavers ( Benchmark ) Reference: s% H9 I% v5 M. D

From: Chen Pengjun Date: 31 Aug 06 cc:

Check Appropriate Box: First

Article Pre-Production Run Production Run X ; H! b1 o2 V5 g: { Q3 X

Part Number: 541-1056-01 P.O. Number: NA Part Description: Sebring Customer: Benchmark Revision: 50 Reference Number: NA

Quantity: 3PCS RMA Number: NA

Date Code: 0540 Date RMA Issued: NA Lot Code: NA Date RMA Received: NA Date 8-D Report Completed: 1 Sep 06

COMPLETION OF THIS 8-D REPORT IS EXPECTED WITHIN 10 WORKING DAYS

D1. Form a team:

Team Leader : Chen Pengjun (Quality Engineer)

Team Members : Justin Wu (Quality Manager), Kelvin Toh (Business Development DirectorWu Donghua(Product Supervisor) Guo Guobing(Process Engineer)

D2. Define the problem or potential problem:

Two points are hitting when the door is closing.

D3. Implement temporary action:

To control the dimension in the weld process uses the jig. D4. Define and verify root cause:

In the stamping process the Angle of products cannot fully fill 90°. And the operator that does not control the Angle and the dimension in the weld process.

D5. Select and verify the corrective or preventive action: Do 100% checking for the 341-1911-01 during the welding process. And control the dimension in 179.66+/-0.25 with the jig. The jig with spring can adjust to control the dimension in the spec.

D6. Implement the corrective or preventive action: ) e5 }1 k1 t- L/ |$ m: s+ t" C* r4 c* n& z( & S. b) W6 c$ D0 |" ?# C2 ' | }" O! j( 1 U5 q0 _- K! O! j5 u& M: 3 z/ A0 N3 P5 Q! e5 e. \0 @0 j- M. L# ( L! X, N1 Y/ t% T1

1. 100% check existing stock.

2. QC will increase the check during the weld process (check the dimension in the 179.66+/-0.25) using the jig.

D7. Prevent the recurrence of the problem or the occurrence of the potential problem:

1. On the stamping process Qc will increase the check to control the Angle 90°±1°

2. In the welding process use the jig to control the dimension.

3. Ensure 100% inspection the dimension within the 179.66±0.25 D8. Provide feedback to the team:

Signature: Date: Signature: Date:

Follow-up:

The problem or potential problem was eliminated. The corrective or preventive action was implemented and it is effective.

Follow-up by:

Completion date: " K' W, k- P+ g1 |, i9 C% ^6 T! J; ]: C U1 D0 z* W T4 s* g* c/ g) ~$ B5 q6 M( O+ {7 I! J; ) d! P$ S0 h5 P3 l6 ; A" G" c6 e+ 7 L- L) F. K6 C* f' P$ g9 & }' B2 A9 Q; N$ t( A# F1 j8 D3 ' q! z- F: K#

- `' j5 v# x" E$ g0 S2 |3

本来我是想上传到网上的!可是文件是word上不了,我压缩后也是上传不了,有没有可以和我说一下如何上传?我再上传多几份供大家参考.

谢谢! 5 {5 W- t6 K4 p; F1 u! V

-

20xx年汽车行业报告

汽车行业报告市场状况及未来发展趋势1汽车产销情况11总体产销情况与20xx20xx年汽车产销触底反弹增速逐年提高不同20xx年我国…

-

汽车项目可行性报告

汽车项目可行性报告项目名称汽车项目可行性报告申报单位xxx联系人xxx电话xxx传真xxx编写时间xxx主管部门xxx撰稿单位郑州…

-

汽车调研报告

项目汽车技术检测调研报告分院汽车技术学院专业汽车维修与检测班级W712211学生姓名单赟晨学生学号二0一一年十二月二十日目录一前言…

-

汽车实践报告

时光荏苒转眼间大学时光已过去一年在这一年多的时间里我除了在学校收获知识还利用课余时间走进社会去体验社会提高动手实践能力增长阅历增强…

-

关于汽车的调查报告

关于汽车产品的调查报告一调查背景自20xx年之后中国汽车行业开始进入爆发式增长阶段特别是随着私人消费的兴起轿车需求量开始迅速攀升并…

-

关于汽车售后服务市场的社会实践报告

暑假里我在新泰“圣起亚汽车集团”进行社会实践,在二个月里维修使我对维修站的整车销售、备件供应、售后服务、维修技术以及信息反馈等有了…

-

达县昌明汽车修理厂关于质量信誉情况的自查报告

达县路通汽车修理厂文件达路通汽修[20xx]3号签发人:廖永超达县路通汽车修理厂关于质量信誉情况的自查报告达县运管所:按照达县公路…

-

关于汽车售后服务市场的社会实践报告

关于汽车售后服务市场的社会实践报告暑假里我在泉州市中国一汽奔腾4S店进行社会实践在二个月里维修使我对维修站的整车销售备件供应售后服…

-

汽车综合性能检查站基本情况和检测质量整改报告

汽车综合性能检测站基本情况和检测质量整改报告编写人刘刚审核人束书忠签发人李庆林叶集交安机动车检测有限公司二零一一年九月二十一日根据…

-

汽车运输公司信誉质量自查报告

汽车运输分公司质量信誉考核自查报告根据安运准字20xx124号文件通告按照陕西省道路客运企业质量信誉考核实施细则对我公司20xx年…

- 8D报告模板(中英文)