JBoss不能加载struts2-core-2.2.3.1.jar,提示:Could not create JarEntryRevision for……

JBoss不能加载struts2-core-2.2.3.1.jar

——提示:Could not create JarEntryRevision for……

学习Eclipse(Kepler)时,使用struts2 2.2.3.1和JBoss EAP 6.02.GA,在启动JBoss时,提示:Could not create JarEntryRevision for……\struts2-core-2.2.3.1 (文件名、目录名或卷标语法不正确。)

在网上查找很长时间才找到一个相关的帖(/topics/380025531),提供了解决办法,为了节省后来学习者的时间,特意写此文档。

原因:这是struts2在jboss下的bug问题,是xwork-core-2.2.3.1.jar的问题。

解决方案:

方法1、(https:///thread/160683)

修改xwork-core的jar包文件com.opensymphony.xwork2.util.URLUtil

//--------------------------------old code----------------------------------------------------

public static final String JBOSS5_VFSZIP = "vfszip";

public static final String JBOSS5_VFSMEMORY = "vfsmemory";

public static boolean isJBoss5Url(URL fileUrl) {

final String protocol = fileUrl.getProtocol();

return JBOSS5_VFSZIP.equals(protocol) || JBOSS5_VFSMEMORY.equals(fileUrl.getProtocol()); }

//--------------------------------end of old code-------------------------------------------

and change it to:

//--------------------------------fixed code----------------------------------------------------

public static final String JBOSS5_VFS = "vfs";

public static final String JBOSS5_VFSZIP = "vfszip";

public static final String JBOSS5_VFSMEMORY = "vfsmemory";

public static boolean isJBoss5Url(URL fileUrl) {

final String protocol = fileUrl.getProtocol();

return JBOSS5_VFS.equals(protocol) || JBOSS5_VFSZIP.equals(protocol) ||

JBOSS5_VFSMEMORY.equals(fileUrl.getProtocol());

}

方法2、

下载修正的包"xwork-core-2.3.1-SNAPSHOT.jar"替换xwork-core-2.2.3.1.jar。

根据上面的链接,找到此方法,但下载地址是错误的,就转到回复中的另一个链接:,再转到链接:,终于找到相应包的下载地址。

xwork-core-2.3.1-SNAPSHOT.jar下载地址:

张家恺2014-11-24

第二篇:Conformance Testing of Soft-Core CAN Controllers

ConformanceTestingofSoft-CoreCanControllers:

ALow-CostandPracticalApproach

ImranSheikh1andMichaelShort2

1EmbeddedSystemsLaboratory,UniversityofLeicester

UniversityRoad,LE17RH,UK

si52@le.ac.uk

2Electroincs&ControlGroup,TeessideUniversity

BoroughRoad,Middlesbrough,UK

m.short@tees.ac.uk

Abstract.Sinceitsintroductionintheearly1980’s,CANhasbecomethede-factocommunicationsprotocolemployedinvehicleandindustrialcontrolap-plications.BeforeanynewdevicecanclaimtosupportCAN-connectivity,exten-siveconformancetestingisnormallyrequiredtodemonstratecompliancewiththeprotocolatthephysicalanddatalinklayers.Tohelpstandardizethenatureofthespeci?ctestplansanddocumentationrequiredforthistesting,theISOhaspublishedasetofdraftstandardsspeci?callyforCANconformancetesting.Todate,mostcommercialCANcontrollersandtransceivershavebeenimplementedatthesiliconlevel,eitherintheformofdedicatedIC’sorason-chipperipheralsofembeddeddevices.ThepracticalimplementationofCANconformancetestershasbeenrealisedusingdedicatedhardwareandspeciallywrittenanalysissoft-ware;thisisapracticalapproachwhentestingandverifyingconformancepriortohigh-volumeICmanufacture.However,recentyearshaveseenanincreasedin-terestintheemploymentofprogrammablelogicdevicessuchasFPGA’sfortheimplementationofCANcontrollersandCAN-enableddevices.Such‘softcore’implementationsareoftenrealisedinsmall-volume(orsometimesevenone-off)batches;insuchcircumstances,costandavailabilityreasonsmaydictatethatde-veloperssimplycannotemploytraditionalCAN-conformancetestingequipment.Tohelpalleviatethisproblem,thispaperproposesalow-costandeasilyimple-mentedmethodwhichwillallowdeveloperstofullytestaCANsoftcoreim-plementation.ThemethodallowsdeveloperstoverifyaCANcoreagainsttherelevantISOstandardsusingonly(low-cost)off-the-shelfdevelopmentboards,coupledwithasimpleanalysistoolsuchasChipscope.Finally,thepaperexten-sivelydescribestheuseofthetestbedintheveri?cationofanopen-sourceCANsoftcoreimplementation.

Keywords:Controllerareanetwork,Conformancetesting,Softcore,Networkprotocolveri?cation.

1Introduction

Conformancetestingisanintegralpartofthedevelopmentstageofanynetworkpro-tocolimplementation.Whenperformedcorrectlyconformancetestingveri?es,toanJ.A.Cettoetal.(Eds.):InformaticsinControlAutomationandRobotics,LNEE85,pp.129–141.

cSpringer-VerlagBerlinHeidelberg2011springerlink.com??

130I.SheikhandM.Short

acceptabledegreeofcon?dence,thattheimplementationofgivensetofprotocolspec-i?cationshasbeencorrectlyinterpretedbythedesignersandhasbeeninstantiatedinaformthatisfreefromerrors.

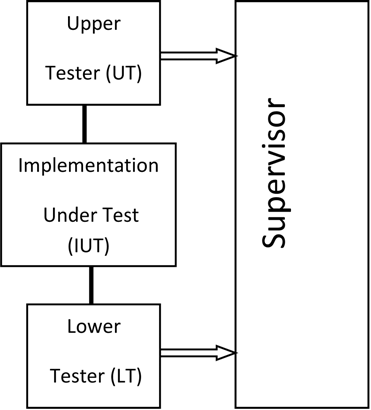

Sinceitsintroductionintheearly1980’s,theControllerAreaNetwork(CAN)pro-tocolhasbecomethede-factocommunicationsprotocolemployedinvehicleandin-dustrialcontrolapplications.InlightofthepopularityofCAN,theISOhasdevelopedastandardexclusivelyaimedatCANconformancetesting.BeforeanynewequipmentdesigncanclaimtobeCANconformant[1],evidenceisrequiredthatshowsthatthetestingproceduresoutlinedin[2]standardhavebeenperformedandpassedwithoutproblem.TheISOdocumentnotonlyspeci?esdifferenttypesofteststhatmustbeper-formedforconformancetesting,butalsospeci?esaTestPlan(TP)architecturebasedonthe[3].TherequiredTPisshownin?gure.1.Ascanbeseenfromthis?gure,theTParchitectureindicatesthatthetestershouldbedividedintotwoparts.The?rstcompo-nentistheLowerTester(LT)whichprovidesthetestpatterngenerationandanalysis.ThesecondistermedtheUpperTester(UT),whichisrequiredtocontainthesoftwaretocontroltheCANImplementationUnderTest(IUT).TheUTisnormallyahostpro-cessororprogrammabledeviceofsomekind,andalsoprovidescoordinationtoconductthetestsbetweentheLTandtheIUT[4].TheUTreceivesstimulus(withdetailsofthetestbeingperformed)fromtheLT,andgeneratesmessagespassedontotheIUT.TheIUTthenprocessesthesemessages,andboththeUTandLTcomponentsmonitoritsbehaviourforconsistencywiththeCANprotocol.Iftheresultissatisfactory,thetestisconsideredpassedandtestingproceedstothenextconformancetest.Itshouldbenotedthatthetestingproceduresthatarerequiredtobeimplementedincludecoverageofcommonerrorconditions,randomizedtestsandalsobittimingtests.Mosttestsarecritical,andthelattercategorybittimingcontainsanumberofteststhatcanbedif?-culttolocalize,andasuitablemeansisrequiredtocaptureanddisplaymultiplelogicsignalsoveranappropriatetimescale.Thistypicallyrequirestheuseofdedicatedhard-wareandLogicanalysers[5].

Traditionally,CANcontrollersandtransceivershavebeenimplementedatthesil-iconlevel,eitherbydedicatedIC’sorason-chipperipheralsofembeddeddevices.Practically,theimplementationofCANconformancetestershasbeendoneusingded-icatedhardwareandspeciallywrittenanalysissoftware,whichisapracticalapproachwhentestingandverifyingconformancepriortohigh-volumeICmanufacture.Themo-tivationforthecurrentworkisasfollows.RecentyearshaveseenanincreasedinterestintheemploymentofCAN-enableddevicesimplementedbyprogrammablehardwaredevicessuchasFPGA’s.Bytheirverynature,such‘softcore’implementationsareoftenneededinsmall-volume(orevenone-off)batches.Inthesecircumstances,costandavailabilityreasonsoftendictatethatitisnotpracticalfordeveloperstousetradi-tionalCAN-conformancetestingequipment.AnongoingprojectwithintheEmbeddedSystemsLaboratory(ESL)attheUniversityofLeicesterrequirestheuseofsuchaCANsoftcore[6].Tohelpalleviatethisproblem,thispaperproposesalow-costandeasilyimplementedmethodwhichwillallowdeveloperstotestaCANsoftcoreimple-mentationforconformancetotherelevantstandardwithouttheneedforexpensiveorproprietaryhardwareinterfacesandlogicanalysers.

ConformanceTestingofSoft-CoreCanControllers

131

Fig.1.ISO9646-1TestPlanArchitecture

Theremainderofthepaperisorganizedasfollows:InthenextSection,wewilldescribetheControllerAreaNetworkinbriefandthenwillpresentareviewofdif-ferentCANconformancetestingimplementationsofthebeforeandafterISOstandardevolved.Section3describestheformationofthecurrenttestbedforCANconformancetesting.Section4presentsthecasestudiesinvolvingtwoofthetestsbeingcarriedoutbytheproposedapproachtoCANconformance.Section5willpresenttheanalyti-calcomparisonofourapproachtotheothertechniquesusedforconformancetesting.Section6presentsourinitialconclusions.

2ControllerAreaNetwork

2.1Protocol

TheControllerAreaNetwork(orsimplyCAN)isoneofthemostwidelyemployedprotocolsforcreatingdistributedembeddedsystems,withapplicationsasfarrangingasvehicleelectronics,processcontrolandmanyotherimportantindustrialapplica-tions[1].SomeofthekeyfeaturesofCANthathaveledtoitswidespreadusein-cludelowoverheads,non-destructivebitwisemessagearbitration,lowmessagelatencyandgooderrordetectingabilities;allfeatureswhicharerequiredforcontrolapplica-tionsrunningonembeddedprocessors[7,8].Asmentioned,theprotocolemploysauniquenon-destructivepriority-basedarbitrationscheme;whenmultiplenodesattempttotransmitmessagessimultaneouslythismechanismensuresthatthehighestprioritymessagegains?rstaccesstothebus.Ifprioritiesarecarefullyassignedtothemessages,andappropriatetiminganalysisisperformed,CANmaybeusedtoimplementseveraldifferenttypesoftime-criticalsystems(e.g.see[7,8,9]).

132I.SheikhandM.Short

Thewired-ANDnatureofthephysicallayer,whichisusedtoachievetheaforemen-tionedpriority-drivenarbitration,requiresthatallnodesinthenetworkachievealogicalconsensusontheinstantaneousbit-patternsappearingonthebuslines.ThisparticularrequirementoftheprotocolactstoseverelylimitboththemaximumtransmissionspeedandbuslengthofagivenCANnetwork;themaximumtransmissionrateisinverselyproportionaltothelengthofthebus,andhasanupperlimitof1MBit/s;duetoitsdesignaCANframemaycarryuptoamaximumof8databytes.Inaddition,thismechanismplacesextremelyspeci?crequirementsonthenatureoftheconformancetestingthatmustplaceforaCANenableddevice;asigni?cantproportionoftheISOteststandardisdevotedtothissingle,criticalaspectoftheprotocol.

2.2CANConformanceTesting

OneoftheearliestCANprototypecontrollerswasnamedDBCAN[10].Thisimple-mentationwastestedusingalogicanalyserandapatterngeneratorcircuit.Astherewasnostandardforconformancetestingatthetimetheprototypewasdeveloped,acommer-cialbasic(asopposedtofull)CANcontrollerwasusedasbenchmarkforveri?cation.Amajordisadvantageofthisschemewastheuseofexternalinterfacemodulestovisu-alizethestateofdifferentDBCANregisters,andthetestingprocedurewassomewhatlimitedinthenumberofsignalchannelsthatcouldbesimultaneouslyanalysed.SincethisisaneededrequirementinthecaseofISOstandardconformancetestingtheabilitytovisualizethestateoflargenumbersofCANregisterssimultaneouslyisaprerequisitesuchasetupislimitedinthisrespect.

AHardwareemulationtechniquewasusedtoverifyaCANsoftcorein[11];?rstly,thesynthesizednetlistisdownloadedintoahardwareemulator.Thisemulatoriscon?g-uredbyaPCandthecommunicationbetweenthetwoiscarriedviaaspeciallydesignedinterfacecardconnectedtotheEISAbus;thisemulatorisalsoconnectedto2commer-ciallyavailableCANchips.Thedrawbackwiththistechniqueisthatagain,customizedhardwarealongwithsoftwareespeciallywrittentocarryouttheconformancetestingisrequired.Additionally,toemulatethebusfailuresandpotentialerrorconditionsonthebusamanualtechniqueofconnectingCANbustotheoutputofindividualnodesisemployed,whichlacksef?ciencyandisnotrobustenoughtocoverallthescenariosgivenwithinISODIS16845.

Aslightlydifferentveri?cationtechniquewasreportedby[12].Theirtechniqueemployedcustomdesignboardswith8051microcontrollersandSJA1000CANcon-trollers,butthismethodinvolvedthedesignofspecializedinterfacehardwareandboardstoassistwiththetestingplan.Specialisedveri?cationarchitecturefortestingautomotiveprotocols(includingCAN)atboththemoduleandchiplevelwasproposedby[13].Again,thisworkrequiresaspeciallydesignedCANveri?cationcomponentaspartofthesilicon,whiletheselectionandimplementationofactualtestsequences,alongwiththeselectionofasuitablemeanstomonitoringbussignals,isleftopenforthetester.

WithrespecttosoftcoreCANimplementations,theCANe-Veri?cation(CANeVC)testbenchhaspreviouslybeendescribed[14].ThiscommercialtestfacilityrequiresaCANspeci?cationcoretobeembeddedinthenetlist;thiscorethenrunsspeci?cteststoverifythebehaviouroftheCANsoftcore.Again,thistechniqueinvolvesa

ConformanceTestingofSoft-CoreCanControllers133

timeconsumingdevelopmentofatestbenchusinganexpensivecommerciallyavail-ableveri?cationIP;additionally,compatibilityissuesoftenarisewhenusingCANimplementationsotherthantheproprietaryimplementationandonlyalimitednumberofprogrammablelogicdevicesaresupported.

Finally,severalexperimentalimplementations(suchasthatreportedby[15]tomea-suresingleparameters-suchasCANbiterrors-ratherthanperformcompletecon-formancetestinghavebeendescribedintheliterature.Suchimplementationshavetypi-callyusedcomplexandnon-trivialmeans,requiringcustomizedhardwareandsoftware.Insummarythen,itcanbeobservedthat-todatespecialisedhardwareand/orsoft-warehasbeenrequiredtoassistwithCANtestingplans.InthefollowingSection,anoveltestingapproachthatreliesonlyupontheuseoflow-cost,standardoff-the-shelfhardwareandsoftwareisdescribed.

2.3ProtocolLimitation

However,theCANprotocolitselfisnotwithoutitsdrawbacks;althoughthebasicrawprotocolissuitableforuseinmanysoftreal-timesystems,itsuffersfromseveralsig-ni?cantproblemswithrespecttohardreal-timesystems,forexampleinsafety-criticaldistributedbrake-by-wiresystems.Thesedrawbacksincluderedundancyissues,atomicbroadcastproblems,lackofprotectionfrombabblingidiotfailuresandinformationthroughputrestrictions.Althoughresearchhasshownthatmanyoftheseissuescanbedealtwithbythecreationofhigher-level,software-basedprotocolextensions(e.g.see[7,8,16]),someproposedsolutionsareeithercomplextoimplementplacingasig-ni?cantcomputationaloverheadonthehostCPUorsimplycannotbeimplementedinsoftwareandahardwaresolutionmustbeadopted[17].Althoughtheproposedchangesareconceptuallyquitestraightforward,implementingthemdirectlyinsiliconiscostlyandhasprovedtobeproblematicforsmall-volumerequirements.AworkablesolutiontothisproblemistoimplementtheprotocolonaPLD;therequiredmodi?cationsmaythenbeachievedwithrelativeease.Thissolutionbringswithitanother,relatedprob-lem;beforeveri?cationofanymodi?cationscantakeplace,itmustbeshownthatthebasicsoftcoreCANimplementationisfullyconformanttotheprotocol,apotentiallycostlyandtime-consumingprocedureinitsownright.

Tohelpalleviatethisproblem,thecurrentauthorshavepreviouslyproposedalow-costandeasilyimplementedmethodinatechnicalreport[18].ThisreportessentiallydescribetheapplicationofthetechniquesdescribedinthepreviousSectiontothecon-formanceofaCANsoftcore.ThefollowingSectioncontainsadescriptionofthetestfacilitythatwasemployedinthesestudies.

3TestBed

Real-timetestingofaCANimplementationisquiteacomplicatedprocedure,andinthiscaseforpracticalreasons,nospecializedhardwareandsoftwarewasavailabletogeneratetherequiredtestingpatternsandmonitorthebehaviouroftheCANsoftcore.Forthisreason,itwasdecidedtouseonlylow-costofftheshelfcomponents.

Inadditiontothesestandardhardwareparts,theChipscopeanalysistool[19]wasusedtovisualizeandcapturethebehaviourofthesoftcore,allowingveri?cationofthe

134I.SheikhandM.

Short

Fig.2.ConformanceTestBed

testingresults.ChipscopeisaXilinxtestingtoolwhichisimplementedbyinsertingasmallcoreontothedevicetobemonitored,allowingmultiplesignalchannelstobecapturedviaaJTAGinterface.Upto16internalsignalportscanbeanalysedinasinglecore,andeachportcanhaveupto256signals.MultiplecorescanbeattachedinaFPGAtoincreasethenumberofsignals[20].IncomparisontoothermeansforcapturingmultipleFPGAsignals,Chipscoperetainsthekeyfeaturesrequiredbutisafractionofthecost.Additionally,tosupportone-offconformancetestingplanswithoutcausingexcessivecosts,afully-featuredevaluationversionisavailablefora60dayperiodafulltestingplancanbeperformedinsuchatimeframe.HencethesefeaturesofChipscopemadeitanobviouschoiceforourCANconformancetestbed.Thenewtestfacilityisshownschematicallyin?gure2.InthenextparagraphswegiveafulllistofthehardwareandsoftwarecomponentsandtoolsusedinbuildingtheTestBed.

3.1Hardware

1.TwoIntegratedboardswithFPGA’s(programmedwithCANsoftcore)andanARM7workingasaHostcontroller.TheseboardsarenamedasSC1andSC2.ThepurposeofusingtwosoftcoresistoverifysimultaneousbehaviourasaCANTransmitter/ReceiveraswellastogeneratespecialpatternsontheCANbususingVIOandadditionalsoftmodulesembeddedwiththesoftcore.

2.TwoARM7MicrocontrollerboardswithIntegratedCANcontrollerandtrans-ceivers(NodeKEandOLin?gure2).TheseboardsareusedasCANReceiverNodesforfurtherveri?cationofthemessagessentbytheCANsoftcore.Theother

ConformanceTestingofSoft-CoreCanControllers135

utilityoftheseCANnodesaretoinduceextraorerroneousbitswhichisarequire-mentoffewtestcasesasmentionedin[2].

The?gure2demonstratea2nodeSoftCore,itcaneasilybeextendedtonnumberofnodesconsideringtheprotocollimitations.

3.2Software

1.XilinxISE[21]forsoft-coreprogramming,synthesis,routingandprogrammingtheFPGA.TheISEisacompleteIDEforFPGAdevelopmentandcontainssomeextrafeatureslikepoweranalysis,optimalroutingandtiminganalysistonameafew.

2.ChipscopeProisusedasanalysistool.TheVIOcoreisusedtogenerateandcontroldifferentbitpatterns.Thesebitpatternscanbesynchronousorasynchronous.

3.TheKeiluVision3IDE[22]withfreeARMtoolsCcompilerwaschosenforprogramminganddebuggingtheMicrocontrollerboards.

Ascanbeseen,thetestbedhasbeenmadeusingCOTShardwareandalsotakingincarethestructureoftheTestPlangivenintheISO9646-1.TheTestBedconsistsoftwoinstancesoftheIUT,themainpurposeofusingthesecondIUTistogenerateerrorsontheCANbusandspecialconditionswhichwereeitherthepre-requisiteforatestcaseorgeneratingspecialbitstreamduringatestforverifyingthebehavioroftheIUT,hencethesecondinstanceofIUTismoreoverworkingastheLTinreferencetotheISO9646-1TP.

TheARMboardswithintegratedCANControllerswereusedeitherasreceivers/transmitterstoverifytheconformanceoftheIUTwithwidelyusedCANcontrollers,andwerealsoemployedtogeneratebiterrorsontheCANbususinganinterruptgen-erationmechanism.Thisschemeishighlysynchronizedasthebitinversionsweredoneatthespeci?cpointwhereitwasrequired;themethodologyemployedfortestpatterngenerationisdescribedinthenextSection.

3.3TestPatternGeneration

Whenusingpatterngeneratorstestvectorsarerequiredtobe?rststored,andaresentontheCANbusonlywhenrequiredthusputtingtheIUTindifferentstatesandallowingitsbehaviourandresponsestobeanalysed.InourproposedtestbedwehaveusedFPGAbasedpatterngeneration,whichisnotonlyeconomicalasnoextrapricewasaddedtothetestsetupbutalsoitisaddedasaseparateVerilog[23]moduletothemainCANCoreanditwillworknon-intrusivelyasthiscodispartoftheCANcorewhichistakingtheroleofanLT.Thishelpedustoaccuratelyproducespecialconditions;forexampleinatestcaseitwasneededtoproduceextradominantbitsontheCANbusafteranIUTworkingasatransmittersendanErrorFrame[2].ThistestpatternwaseasilyachievedbymodifyingtheVerilogmoduleforErrorFlaggenerationtoproduceextradominantbits,asillustratedbythecodefragment:

136I.SheikhandM.

Short

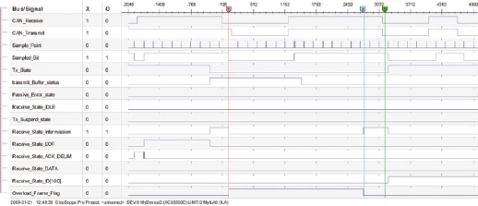

Fig.3.TransmittersnapshotforOverloadframetestcase

reg[3:0]Error_Flag_Counter;//changedfromreg[2:0]

always@(posedgeClockorposedgeReset)

begin

if(rst)

Error_Flag_Counter<=4’d0;

elseif(Error_Frame_End|Error_frame_Start)

Error_Flag_Counter<=#delay4’d0;//changedfrom3’d7

elseif(Error_Frame&Transmit_Instance&Error_Flag_Counter<4’d11))Error_Flag_Counter<=#delayError_Flag_Counter+1’b1;

end

always@(Error_frameorError_Flag_Counter)

begin

if(Error_frame)

begin

if(Error_Flag_Counter<4’d11)//changedfrom3’d7

begin

if(Node_Error_Passive)

Tx_CAN=1’b1;

else

Tx_CAN=1’b0;

end

end

end

4TestCases

TheproposedtestfacilitywasemployedtotesttheCANconformanceofthecustomcre-atedCANsoftcore,writteninVerilog.AsthenumberoftotalnumberoftestcasestoconsiderinanysingleCANconformancetestplanisnumerous,itisbeyondthescopeof

ConformanceTestingofSoft-CoreCanControllers137

thecurrentpapertopresentcomprehensivetestresults;suchtestresultsareavailableintheformoftechnicalreport[18].However,inthisSectionwewillpresenttwotestcasesthathelphighlightthemainfeaturesoftheproposedfacility.Bothtestswerecarriedoutsuccessfully,andaredescribedinthefollowingtwoSections.

4.1OverloadFrameManagement

ThistestisapartoftheOverloadFrameManagementclass[2].Thistestveri?esthatanIUTwillbeabletotransmitadataframestartingwiththeidenti?erandwithouttransmittingSOF,whendetectingadominantbitonthethirdbitoftheintermission?eld.ThistestinvolvestwoinstancesoftheIUTandtheARM7Microcontrollerboards.Thetestwillbesetupusingthefollowingorganization:

1.BothoftheIUT’smustbeindefaultstatereadyfortransmissionorreceptionaccordingtothesetupsentbytheHostController.

2.TheIUTactingastheTransmitterissettotransmittwodataframesasprogrammedintheHostprocessor.

3.TheReceiverIUTwillbesettorequestanOverloadframeafterreceptionofthe?rstframe.

4.AfterthecompletionoftheOverloadFrameonthethirdbitoftheIntermission?eld(NormallytheIntermission?eldisasequenceofthreeRecessivebits)issettodomi-nantbytheFaultinjectornodei.e.K.E.

5.Thetransmittermustnotconsideritasabiterrorandshouldn’tsendaDominantlevelSOFandconsiderthedominantbitoftheIntermission?eldastheSOF.

6.Normalreceptionofthemessageshouldtakeplace.

Thistestwassuccessfulwithdesiredresultsasstatedinthepurposeofthetest;theobser-vationonthetransmitternodefromtheChipscope-shownin?gure3isasfollows:

1.LeftofMarker‘T’TheTxstate?agishighindicatingongoingtransmission,ReceivestateDataandACKDELIMindicatingasuccessfultransmissionwhilethenodeiserroractive.

2.AtMarker‘T’thereisanerrorontheReceivestateintermission?eldgeneratinganoverloadframewithOverloadFlagofsixdominantandOverloaddelimiterof8bitsascanbeseenbythecountofsamplepoint.

3.AftertheOverloadframeanintermission?eldsignalcanbeseenattheMarker‘X’.

4.Thethirdbitofintermission?eldisisadominantbitascanbecountedbetweenMark-ers‘X’and‘O’thenumberofsamplepointsis2andthethirdsamplepointisadominantbit.

5.JustaftertheMarker‘O’wecanseetheReceiveStateID[10:0]goinghighwithoutanySOF.TheIdenti?er?rst4bitsaredominantasrequiredbytheTestcase.

4.2SuspendedTransmissionFieldTest

ThepurposeofthistestistoverifythataPassivestateIUTactingasatransmitterdoesn’ttransmitanyframebeforetheendofasuspendedTransmission?eldfollowinganErrorFrame.

138I.SheikhandM.

Short

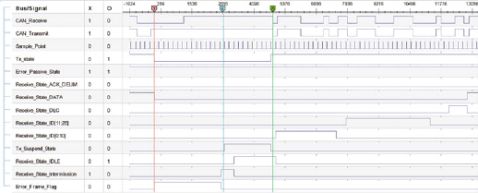

Fig.4.Transmittersnapshotforsuspendedtransmissiontestcase

ThesetupforthistestistoputtheTransmitterIUTintoErrorPassivestateandthenintroduceabiterrorduringtransmission.TheIUTwillsendaPassiveErrorFlagwhichisoverwrittenbyActiveErrorFlagfromparticipatingCANnodes,theIUTwillreceive7dominantbitsastheErrordelimiter.AfterthecompletionoftheErrorFlag,theIUTwillsendthependingdataframeoncetheSuspendedTransmissionFieldisover.

Thistestwassuccessfulwithdesiredresultsasstatedinthepurposeofthetest;theobservationonthetransmitternodefromtheChipscope-shownin?gure4isasfollows:

1.LeftofMarker‘T’TheTxstateFlagishighindicatingongoingtransmissionwhenabiterrorsetthenodetosendanErrorFrame,thenodeisErrorPassive.

2.BetweenMarker‘X’and‘O’thereisnotransmissionwhentheTxSuspendstateishighwhichisindicatedbytheTXStatelowstatusalthoughincaseoferrorrecoverythere-transmissionofthemessageiscarriedsoonaftertheintermission?eld.

3.AstheTxSuspendstateissettolowafter8bittimesthentheSOFisindicatedbyCANReceiveandCANTransmitsignalswhichchangestodominantstate.

4.RestoftheReceivestatesignalsindicatesthere-transmission.

5ComparativeStudy

ThisSectionpresentsacostand?exibilitycomparisonbetweenconventionalCANcon-formancetestinghardwareandsoftwarewiththeapproachthathasbeendiscussedinthispaper.The?rstobservationisthatthenextfacilitydoesnotrequireexpensiveCANPCinterfacecards[24,25]whicharenormallyrequiredforCANconformancetesting[26].ThesecardsareusedtocaptureCANbusdatatoanalysetheinternalstatusofdifferentreg-istersandtologtheevents;thesecardsnotonlyrequiredthehardwarebutalsospecializedsoftware[27]alongwithinterfacecableswhichcanalsoaddtothecostandcomplexityofthesetup.InourproposedimplementationwecananalysetheinternalstateofCANIUTdirectlyusingChipscope,andalsobyusingtheKeiluVision3IDE.ThisIDEcanrunanonlinedebugontheCOTSARMboards,whicharesigni?cantlycheaperincomparisontospecialisedCANinterfaceCards.TheKeilIDEcandisplaythestatusofalltheCAN

ConformanceTestingofSoft-CoreCanControllers139

registershenceprovidingususefulinformationinveri?cationofthestatusoftheCANbusandthedatabeingtransmittedandreceived.Inaddition,thereareseveralkeyadvantagesofourproposedtestbedusingChipscopeoverhardwarelogicanalysersystems:

1.Thestandardbenchanalysersdoesn’tshowenoughsignalsasrequiredincaseofCANconformanceasillustratedinsection4.ThereareLogicanalysersystemswhichcanshowlargenumberofsignalssimultaneouslywithlargedatawidths[28]buttherepricesare10timesmorethanIntegratedLogicanalyser.

2.NormalBenchanalyserscanshowMegasamples[29,28],whiletheChipscopeislim-itedtoaSamplewidthof16K,weovercomethisproblembyusingDigitalclockMan-ager[30]whichcandivideormultiplythesystemclockby‘n’times,theboardweusedinoursystemcandividethesystemclockby16timeshencewewereabletocapture16timesmoresamplethanonsystemclockwhichcaneasilycapture3to4completeCANmessagesinasingletrigger.

3.AdditionalprobeswithwidenumbersofI/OpinsarerequiredtointerfacewiththeLogicanalyserswhileChipscopecancarrymagnitudeofthesesignalsusingasimpleJTAGcable,althoughtherearefewsolutionlikeAgilent’sFPGAtraceport[31]whichuseasimpleinterfacetoanalysemultiplesignalsbutitalsorequiresaspecializedhardwareandChipscopeprotool.

4.NotonlyallI/OsignalsareaccessiblethroughChipscopebutalsointernalwirescanbetraced[32]whicharereallyhelpfulinConformancetestingspeciallywhensettinguptriggeringconditionswehavelotmoreoptionstosetupatriggerconditionforexampleinthetestcasesdiscusseditisreallyeasytosetupatriggerconditiontowaitforanErrorFrame?agsignalgoestohightoanalyseanerrorcondition,whileforexternalLogicanalysersonlyI/Osignalsareavailable.

6ConclusionsandFutureWork

InthispaperwehavepresentedanapproachtoutilizeVirtualI/OsandIntegratedLogicAnalyserstoperformCANconformancetestinginaccordancewiththeISOstandards.IthasbeenshownthatthefacilityiscapableofperformingthefullrangeoftestrequiredandspeciallyrelatedtoCANbittimingtestsconformingtotherelevantCANstandard.Inconclusion,thisfacilitycanbeassembledandusedforafractionofthecostofaregu-lartestfacilityforCANconformance.Afulllistofthehoweachindividualtestmaybeimplementedwhenusingafacilitysuchasthishasbeendescribedin[18].

Asa?nalnote,itcanbeseenthattestfacilitythathasbeendescribedisnotrestrictedtotheCANprotocol,andwithsuitablemodi?cationscanbeusedtotestconformanceofmanyalternatenetworkprotocols,forexample[33].

Acknowledgements.TheworkinthispaperissupportedbytheawardofaPhDscholar-shiptoSheikhImranfromtheNWFPUniversityofEngineering&Technology,Peshawar,PakistanthroughtheHigherEducationCommissionofPakistan.

140I.SheikhandM.Short

References

1.11898:1993(E),I.:Roadvehiclesinterchangeofdigitalinformationcontrollerareanetwork(can)forhighspeedcommunication(November1993)

2.ISO16845.Roadvehicles-controllerareanetwork(can)-conformancetestplan

3.ISO9646-1.Informationtechnology-ISO-conformancetestingmethodologyandframework-part1:Generalconcepts

4.Carmes,E.,Junier,C.,Aussedat,F.:Canconformance:Methodologyandtools,keynotespeech.In:CANinAutomationProceedingsof3rdiCC,Paris(October1996)

5.Lawrenz,W.,Kinowski,P.,Kircher,G.:Canconformancetesting-thedevelopingisostandardandnecessaryextensions.In:ProceedingsofInternationalTruckandBusMeetingandExpo-sition,Indianapolis,Indiana(November1998)

6.Sheikh,I.,Pont,M.J.,Short,M.:Hardwareimplementationofashared-clockschedulingproto-colforcan:Apilotstudy.In:4thUKEmbeddedForum,UniversityofSouthampton(September2008)

7.Short,M.,Pont,M.:Fault-toleranttime-triggeredcommunicationusingcan.IEEETransactionsonIndustrialInformatics3(2),131–142(2007)

8.Broster,I.,Burns,A.:Timelyuseofthecanprotocolincriticalhardreal-timesystemswithfaults.In:13thEuromicroConferenceonReal-TimeSystems,pp.95–102(2001)

9.Pedreiras,P.,Almeida,P.:Edfmessageschedulingoncontrollerareanetwork.ComputingandControlEngineering13(4),163–170(2002)

10.Kirschbaum,A.,Renner,F.M.,Wilmes,A.,Glesner,M.:Rapid-prototypingofacan-buscon-

troller:acasestudy.In:proceedingsofSeventhIEEEInternationalWorkshoponRapidSystemPrototyping,June1996,pp.146–151(1996)

11.Winter,A.,Bittruf,D.,Tanurhan,Y.,Muller-Glaser,K.D.:Rapidprototypingofacommuni-

cationcontrollerforthecanbus.In:ProceedingsofSeventhIEEEInternationalWorkshoponRapidSystemPrototyping,pp.152–157(1996)

12.Nimsub,K.,Dawi,K.,Kyuhyung,C.,Jinsang,K.,Wonkyung,C.:Designandveri?cationofa

cancontrollerforcustomasic.In:CANinAutomationProceedingsof10thiCC(2005)

13.Zarri,G.,Colucci,F.,Dupuis,F.,Mariani,R.,Pasquariello,M.,Risaliti,G.,Tibaldi,C.:On

theveri?cationofautomotiveprotocols.In:ProceedingsofDesign,AutomationandTestinEurope,March2006,vol.2,pp.6–10(2006)

14.DiBlasi,A.,Colucci,F.,Mariani,R.:Y-canplatform:Are-usableplatformfordesign,veri?-

cationandvalidationofcan-basedsystemsonachip.In:ETS2003Symposium(2003)

15.Ferreira,J.,Oliveira,A.,Fonseca,P.,Fonseca,J.A.:Anexperimenttoassessbiterrorratein

can.In:3rdinternationalworkshoponreal-timenetworksRTN2004,Proceedings(June2004)

16.Ayavoo,D.,Pont,M.J.,Short,M.,Parker,S.:Twonovelshared-clockschedulingalgorithmsfor

usewith’controllerareanetwork’andrelatedprotocols.MicroprocessandMicrosyst.31(5),326–334(2007)

17.Sheikh,I.,Short,M.:Improvinginformationthroughputincontrollerareanetworks:Imple-

mentingthedual-speedapproach.In:Proceedings8thInternationalWorkshoponReal-TimeNetworks,Dublin,Ireland(June2009)

18.Sheikh,I.,Short,M.:Canconformancetesting-anewapproach.In:TechnicalReporttech-

reportESL-09-01,ESL,EngineeringDepartment,UniversityofLeicester(February2009)

19.Xilinx.ChipscopeProSoftwareandCores(January2007)

20.Oltu,O.,Milea,P.,Simion,A.:Testingofdigitalcircuitryusingxilinxchipscopelogicana-

lyzer.In:ProceedingsInternationalSemiconductorConference,CAS2005,vol.2,pp.471–474(2005)

21.Xilinx.Isefoundation,/ise

22.Keil.uvisionidetool(2008),/uvision

ConformanceTestingofSoft-CoreCanControllers141

23.IEEE.IEEEstandardforveriloghardwaredescriptionlanguage.IEEEStd1364-2005(Revision

ofIEEEStd1364-2001),1–560(2006)

24.NationalInstruments.1Port,HighSpeedCAN,USBInterface(2008)

25.Softing,A.G.:CAN/CANopen/DeviceNetInterfaceboards(2007)

26.Lawrenz,W.,Kinowski,P.,Kircher,G.:Canconformancetesting-stateoftheartandtestexpe-

rience.In:Proceedingsof5thInternationalCANConference,ICC1998,SanJose,California(1998)

27.NI.Labview8.6(2009)

28.Agilent.Serieslogicanalysissystem16900mainframes(2008)

29.Tektronics.Tla5000blogicanalyzers(2009)

30.XilinxInc.UsingDigitalClockManagers(DCMs)inSpartan-3FPGAs,ApplicationNote

(2003)

31.Agilent.Deepstoragewithxilinxchipscopeproandagilenttechnologiesfpgatraceportana-

lyzer

32.Lee,T.,Fan,Y.,Yen,S.,Tsai,C.,Hsiao,R.:Anintegratedfunctionalveri?cationtoolforfpga

systems.In:SecondInternationalConferenceonInnovativeComputing,InformationandCon-trol,ICICIC2007,p.203(September2007)

33.Fuhrer,T.,Muller,B.,Dieterle,W.,Hartwich,F.:Time-triggeredcommunicationoncan(time-

triggeredcanttcan).In:ProceedingsofiCC2000,Amsterdam,TheNetherlands(2000)

-

自我评价总结

尊敬的领导,您好,我叫XXX,我于20xx年x月1号来公司报到,经过七天培训,一年的车间实习,对公司有了一定的了解,也对自己有了一…

-

供热工作总结表彰大会

20xx—20xx年度供热工作总结表彰大会同志们:大家好!春回大地、万象更新。我们告别了成绩斐然的20xx年,迎来了充满希望的20…

-

市场营销学生座谈会总结

市场营销教研室学生座谈会总结本次座谈会主要是通过学生代表,听取学生对课堂教学、教学管理、教师授课等问题的意见与建议。大部分同学通过…

-

毕业生实习总结

河南科技学院新科学院毕业生实习总结院系:经济与管理系专业:信息管理与信息系统班级:061班姓名:王蕊实习单位:新乡市政法委职位:文…

-

20xx年计免工作总结

计免工作总结一年的工作接近尾声,我院的计划免疫工作在县疾控中心和上级主管部门的正确领导下,全体职工团结一致,共同努力,圆满完成预期…