WCB材质证明书

温州冶金机械测试研究所

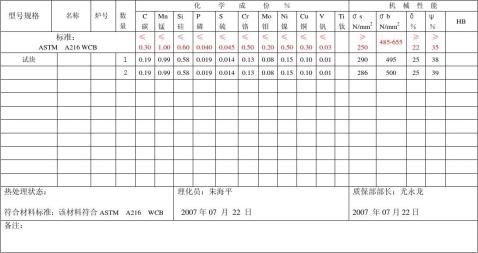

理 化 报 告

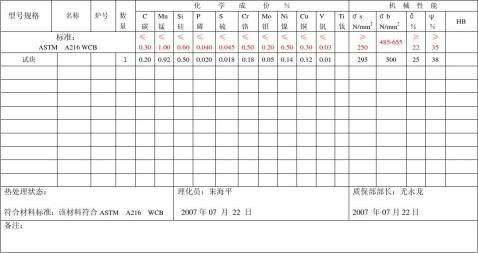

温州冶金机械测试研究所

理 化 报 告

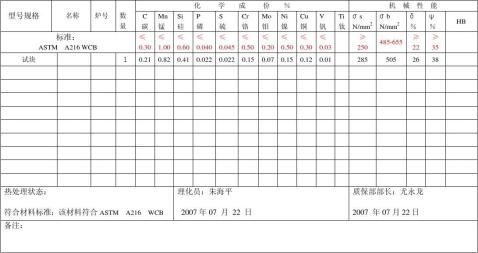

温州冶金机械测试研究所

理 化 报 告

第二篇:WCB材质证明

Proval Industrial

Co.,Ltd.

No.11. Youth 9th Rd,Youth Industry Park,Dajia, Taichung Hsien,Taiwan R.O.C

TEL: 886-4-26816566 (REP.) FAX:886-4-26815279

E-mail:proval@ .tw NO.4278B Inspection Certificate (EN 10204-3.1) PED QMS Certificate No.: 01 202 ROC/Q-02 0064

Customer:成澤 Order-No:FK-798694(TPI0901098-01~17) Certificate -No.:A090603-1

Specification Material Melting process, Heat Treatment Marking

??PED (97/23/EC), Annex 1, section 4 and section 7.5 ■ S.E.P. WCB ASTM A216 (E): electric furnace

■heat to 950℃ Hold 1 hours and air cool. ■ Grade of Material ■ Nominal Size ■ Nominal Pressure ■ Heat Number ?? Year ?? Type No.

??CE Marking

Article

Melter Mark Item No.

??PROVO DN (Size)

PN (Class)

Quantity (PCS)

Heat No. Specimen No.

Extend of material delivery

1

M301

PN Class

4” SW

1000 PSI

Shell strength testing

17

NXI.H3M.F3M.J3M.MII.PII.OII.I3M.G3M.NII.LHO.IHO.JHO. MHO.KHO.PHO.HHO.OHO.NHO

Closure testing

Leak and pressure test according to □ pr EN 12266-1 ■ ANSI B16.34-API 598

Size

Result

Duration

Test Pressure

Test medium

Duration

Test Pressure

Test medium

M301 4” SW 1000 PSI 80 BAR

Water

120 sec

7 BAR

Air

120 sec

OK

Result The requirements are fulfilled, as listed in Annex 1.

Place: Dajia

Date:JUN 3, 2009 Works inspector:

Proval Industrial Co.,Ltd.

No.11. Youth 9th Rd,Youth Industry Park, Dajia, Taichung Hsien,Taiwan R.O.C

TEL: 886-4-26816566 (REP.) FAX:886-4-26815279

E-mail:proval@ .tw NO.4278B

Inspection Certificate (EN 10204-3.1) PED QMS Certificate No.: 01 202 ROC/Q-02 0064 Customer:成澤 Order-No:FK-798694(TPI0901098-01~17) Certificate -No.:A090603-1 Annex 1 : Test Results

A) Chemical analysis

Heat No. ASTM A216

WCB

C % <0.30

Si % <0.60

Mn % <1.00

P % <0.040

S % <0.045

Ni % <0.50

Cr % <0.50

Mo % <0.20

NXI H3M F3M J3M MII PII OII I3M G3M NII LHO IHO JHO MHO 0.268 0.597 0.957 0.025 0.008 0.031 0.109 0.207 0.482 0.814 0.017 0.006 0.198 0.351 0.195 0.509 0.757 0.019 0.008 0.139 0.289 0.203 0.574 0.999 0.017 0.007 0.190 0.376 0.223 0.496 0.824 0.028 0.009 0.064 0.289 0.219 0.533 0.924 0.026 0.008 0.039 0.121 0.229 0.527 0.887 0.026 0.007 0.040 0.142 0.207 0.491 0.835 0.018 0.007 0.201 0.352 0.206 0.515 0.809 0.014 0.006 0.073 0.154 0.218 0.584 0.907 0.023 0.007 0.069 0.207 0.208 0.582 0.928 0.017 0.007 0.091 0.186 0.239 0.531 0.893 0.020 0.009 0.038 0.129 0.222 0.584 0.896 0.018 0.008 0.048 0.115 0.229 0.585 0.940 0.017 0.008 0.091 0.183 0.008 0.041 0.033 0.044 0.013 0.009 0.010 0.041 0.023 0.017 0.025 0.007 0.021 0.026

B) Tensile test /Hardness /Charpy (Test Temperature R.T.)

Rp 0.2 Specimen No.

Proof Stress Strength Energy Charpy Impact

? ASTM A216

>22 -- WCB

NXI 311.6 528.3 23.2 - H3M 313.5 503.5 24.6 - F3M 326.4 512.7 24.0 - J3M 308.4 508.4 24.4 - MII 308.4 513.9 25.1 - PII 304.5 517.5 24.5 - OII 306.1 504.7 24.2 - I3M 323.7 504.1 24.2 - G3M 322.1 511.6 25.2 - NII 313.5 504.3 24.0 - LHO 326.5 525.4 24.0 - IHO 320.4 534.7 26.4 - JHO 339.4 515.4 24.6 - MHO 334.2 516.8 24.5 - C) Dimensional check and NDT

result

Visual inspection & dimensional check Surface crack inspection

OK N/A

Radiographic examination

Intergranular corrosion testing (ASTM A 262-91)

N/A N/A

D) Remarks :

Delivery Condition : □ Pickling 5 Anti-rust

Place:Dajia Date:JUN 3, 2009 Works inspector:

Proval Industrial Co.,Ltd.

No.11. Youth 9th Rd,Youth Industry Park, Dajia, Taichung Hsien,Taiwan R.O.C

TEL: 886-4-26816566 (REP.) FAX:886-4-26815279

E-mail:proval@ .tw NO.4278B

Inspection Certificate (EN 10204-3.1) PED QMS Certificate No.: 01 202 ROC/Q-02 0064 Customer:成澤 Order-No:FK-798694(TPI0901098-01~17) Certificate -No.:A090603-1 Annex 2 : Test Results

B) Chemical analysis

Heat No. ASTM A216

WCB

C % <0.30

Si % <0.60

Mn % <1.00

P % <0.040

S % <0.045

Ni % <0.50

Cr % <0.50

Mo % <0.20

KHO PHO HHO OHO NHO 0.213 0.566 0.897 0.017 0.007 0.124 0.325 0.196 0.577 0.891 0.012 0.007 0.045 0.087 0.266 0.546 0.906 0.018 0.011 0.048 0.116 0.225 0.585 0.957 0.015 0.007 0.053 0.109 0.221 0.582 0.938 0.017 0.008 0.091 0.184 0.026

0.022 0.022 0.028 0.026

B) Tensile test /Hardness /Charpy (Test Temperature R.T.)

Rp 0.2 Specimen No.

Proof Stress Strength Energy Charpy Impact

? ASTM A216

>22 -- WCB

KHO 321.6 525.8 24.0 - PHO 316.5 522.6 24.0 - HHO 310.4 524.9 24.1 - OHO 320.8 556.4 25.1 - NHO 320.6 512.8 25.4 -

E) Dimensional check and NDT

result

Visual inspection & dimensional check Surface crack inspection

OK N/A

Radiographic examination

Intergranular corrosion testing (ASTM A 262-91)

N/A N/A

F) Remarks :

Delivery Condition : □ Pickling 5 Anti-rust

Place:Dajia Date:JUN 3, 2009 Works inspector:

-

【参考】党员证明材料格式

黑龙江中公教育务员考试交流群264578887参与群内每日互动也可以微信添加hljoffcn521为好友我们将把黑龙江省公务员考试…

-

入党证明材料范文

中共支部委员会你处发来的关于武大郎同志培养入党的函调证明材料信我处已收阅现将武大郎同志的基本情况介绍如下武大郎同志于x年x月至x年…

-

质量数量证明书样本

质量数量证明书QUALITYANDQUANTITYCERTIFICATENO合同号CONTRACTNO99JP01M63I8406…

-

保险证明材料

梅安中学参保学生出险证明中国人民财产保险股份有限公司安徽省分公司张海洋男13岁系我校七1班学生于20xx年10月28日晚自习19时…

-

产品质量合格证明书

产品质量合格证明书合同号项目名称设备名称规格型号编号数量谨此证明设计制造和试验均符合合同的要求其认可的偏差与合同的规格标准一致经检…

-

钢筋原材质量证明书

系统编号SYSTEMNO0080354469000010收货单位PURCHASER质量记录编号TABOFQUALITY生产许可证号…

-

钢筋材质证明书

钢材质量证明抄件湘质监统编施20xx33核查其铭牌与抄件是否相符或到经销单位核查其材质证明原件的真实性钢材质量证明抄件湘质监统编施…

- 材质证明书模板

- 不锈钢材质证明书

-

Hastelloy C-22 材质证明书

HastelloyC22UNSN06022WNr24602HastelloyC22的化学成分此合金具有以下特性HastelloyC…

-

工作业绩证明材料

工作业绩证明材料一、基本情况创世纪技能培训学校XX年正式挂牌成立,学校占地面积XX多平方米,教室6间,实习操作场地4处,面积XX多…