6KV高压开关柜调研报告

35/6kV变电所高压开关柜

调研报告

机运工区

二〇##年六月二十九日

35/6KV变电所高压开关柜调研报告

一、问题提出

高煤公司35/6kV变电所内的35面6kV高压开关柜为无锡市江南开关厂生产的XYN1-10型开关柜,于1997年安装使用,目前存在以下问题:

1、该型开关柜在柜门打开时不能断电,无法起到安全保护作用,不具备国家标准GB3906-2006《3.6kV~40.5kV交流金属封闭开关设备和控制设备》规定的“五防”功能(“五防”指:1、防止带负荷合闸。2、防止带接地线合闸。3、防止误入带电间隔。4、防止带电挂接地线。5、防止带负荷拉刀闸。),不能满足国家煤矿安全监察局20##年下发的《煤矿机电安全质量标准化》要求。

2、该型开关柜本体小车操作机构使用时间长,磨损老化严重,致使部分开关柜已不能正常分合闸。

3、开关柜厂家早已淘汰该系列开关柜,柜中本体厂家早已停产,零配件无处购买,造成矿井供电安全隐患。

二、调研方向

1、具有“五防”功能的6kV高压开关柜,并采用新型永磁式操作机构高压真空断路器。

2、开关柜有防越级跳闸功能和0.2级计量系统的微机综合保护器,具备远程通讯和集中控制功能,能实现矿井供电系统综合自动化控制。

三、调研时间

20##年6月26日—6月27日

四、调研地点

无锡军工智能电气股份有限公司

五、调研人员

郭伟、赵振华、乔峰

六、调研具体情况

(一)生产厂家简介

无锡军工智能电气股份有限公司创建于1992年,主要从事高低压配电装置及系列防爆配电装置的研发、生产及销售,是一家具有自主研发能力的高科技型企业,也是江苏省近年来重点发展培育的高新技术企业。无锡军工智能电气股份有限公司注册资本6550万元,矿用准入资格证齐备,管理机构健全,并且拥有多个全资子公司和多个驻外办事机构。该公司在矿用高压真空配电装置方面获得15项国家专利,并在煤矿井下高低压配电系统行业创造了七个第一,受邀参与《矿用一般型高压真空开关柜》国家标准的起草,是起草单位中唯一的一家定点生产型单位。公司生产的产品遍布全国21个省1000多个大小矿区,牢牢占据着国内煤炭行业的主流市场。

(二)产品介绍

1、产品名称:矿用一般型手车式高压真空配电装置

2、产品型号:KYGC-Z

3、产品用途: 本产品主要用于矿井井上下无瓦斯煤尘爆炸的供电系统中,作为三相交流50Hz电压7.2kV或12kV电气设备的配电、保护和控制之用。

4、使用范围:

①安装高度不超过海拔2000m。

②环境温度:-5℃~40℃。

③周围空气相对湿度不大于95%(在25℃时)。

④无剧烈震动和冲击的地方。

⑤在无足以腐蚀金属和破坏绝缘的气体及蒸气的环境中。

5、开关柜主要技术参数

(三)产品特性介绍

1、优点:

①本开关柜为户内封闭式,具有结构新颖、操作维护方便、体积小、重量轻、安全可靠等特点,防护等级为IP54,符合国家标准规定,使用及维护方便。

②本开关柜采用独特的手车室落地门,门的背面铺有手车导轨,手车与落地门通过自推器相连。打开落地门,手车在自推器的作用下,自动从工作位置拉开至试验位置,实现了“开门断电”重要安全防护措施;反之关上落地门,手车自动由试验位置推入工作位置。手车室内装机械和电气连锁机构,操作顺序严格符合“五防”要求。

③本开关柜的一次方案组成灵活多样。真空断路器、电压互感器、控制变压器、电流互感器、操作过电压保护装置等一次元件安装在断路器手车上,检修维护十分方便,并保证了开关柜的可靠性和安全性。

④所有一次绝缘件均采用SMC高绝缘性能粉末一次压铸而成,即保证了可靠的绝缘性能又保证了机械强度。触头罩在动触头未插入时,有一挡板自动放下隔离高压;当动触头插入时,动触头顶开挡板,此时落地门已合上,保证操作人员的安全。动静触头安装了温度在线检测系统,能够对运行中的动静触头温度进行实时检测。

⑤本开关柜配备ZN90Y型双稳态永磁机构高压真空断路器,该断路器操作机构可动部件少(仅为9个),机械寿命长,磨损小,操动机构引起故障的概率大大降低,使得断路器真正实现免维护。

⑥母线室及电缆室的盖板需专用工具才能打开,盖板上有警告牌,并且电缆室安装高压带电显示器,防止由于未停掉反馈电源而引起机电事故。

2、缺点

①本开关柜永磁断路器不具备手动带负荷合闸功能(容易拉弧),给紧急情况下恢复供电带来困难。

②本开关柜使用本厂自行研发的高压综合保护器,无法与我公司供电自动化运行平台相兼容。

七、对比分析

1、我公司现用高压开关柜与无锡军工生产的开关柜性能比较:

2、弹簧操动机构和永磁操动机构的比较

(1)弹簧操动机构是利用交、直流两用电动机对弹簧进行预储能,利用弹簧的弹性势能去进行分、合闸操作的。优缺点如下:

由于弹簧操动机构产品的可靠性不易保证,限制了真空断路器向电气寿命长、免维护等要求更高的方向发展。鉴于以上不足,近年来,一种将永久磁铁应用于操动机构中的新型的“永磁操动机构”越来越受到电力行业的关注。

(2)永磁操动机构

永磁操动机构主要由永久磁铁和分、合闸控制线圈等部件组成,是用永磁体去实现真空断路器合闸保持和分闸保持的一种新型的电磁操动机构。当合闸控制线圈通电时,线圈所产生的磁拉力会使动铁心向下运动,然后由永久磁铁将动铁心保持在合闸位置;当分闸线圈通电时,动铁心向反方向运动,同样由永久磁铁将它保持在分闸位置。由于该机构在控制线圈不通电流时动铁心有两个稳定工作状态(合闸或分闸),故也称为双稳态永磁操动机构。

永磁操动机构的优、缺点

(3)弹簧操动机构与永磁操动机构的技术参数比较

八、结论

通过现场调研及比较分析,35/6kv变电所高压开关柜推荐使用由无锡军工智能电气股份有限公司生产的KYGC-Z型矿用一般型手车式高压真空配电装置,并且采用ZN90Y-7.2型户内交流高压永磁机构真空断路器。

特殊说明:

1、开关柜高压综合保护装置需配备北京广大泰祥自动化技术有限公司生产的地面用高压综合保护装置(该保护具有防越级跳闸功能,具备远程通讯和集中控制功能)。原因是我公司的供电自动化运行平台为北京广大泰祥自动化技术有限公司研制的煤矿电力监控系统,无锡军工智能电气股份有限公司生产的高压综合保护装置与其无法兼容。

2、目前我公司35/6kv变电所6KV开关柜的操作电源为容量为40Ah,而无锡军工生产的KYGC-Z永磁型开关柜要求操作电源60Ah 以上才能可靠运行。

九、结束语

通过此次调研,使我们掌握了高压真空配电装置未来的发展方向,对高压真空配电装置的原理有了更深一步的了解,增强了对高压永磁机构真空断路器的认识,我们要将调研所学到的前沿技术充分利用到煤矿的生产中去,为打造本质安全型矿井,做出应有的贡献。

第二篇:6KV高压开关柜安装调整施工工艺浅析

ABB 6KV高压开关柜安装调整施工工艺浅析

敬承风

(山东电力建设第二工程公司 山东省济南市工业北路297号)

本程序为了确保ABB 6KV高压开关柜(ZS1/ZVC+)安装调整的正确性、安全性、可靠性,规定了6KV高压开关柜的安装工艺、顺序以及施工中应注意的事项。以有效的控制施工过程及质量,确保工程高质量的按期完工。

This procedure specifies installation process, installation sequence and precautions during construction to ensure the correctness, safety and security of ABB 6KV HV Switchboard (ZS1/ZVC+) installation.

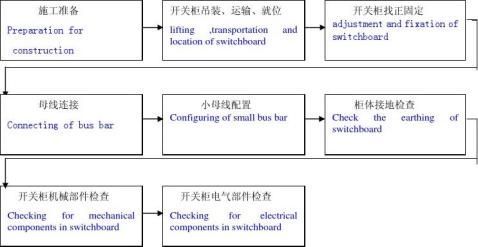

1. 6KV高压开关柜安装调整的施工工艺流程图:

2. 施工准备

Preparation for construction

2.1 施工前仔细审阅图纸,熟悉系统;了解并执行DEP63.10.08.11-CSPC中4.4.1对传导试验的要 求

Check drawings and comprehend the system before construction. Comprehend and conducted the Conductivity tests on main bus bar and earthing bar according to the requirements in Section 4.4.1 of DEP63.10.08.11-CSPC。

2.2了解规范和标准的要求,掌握质量要求和验收标准,编写质量检验计划, 编写及准备符合DL/T 标准的安装记录表;了结掌握ABB的安装和调试手册的要求

Comprehend the requirements of specifications and standards, be familiar with the requirements of quality and standards of acceptance, compile quality inspection plan, compile and preparative form of DL/T standard shall be used to record the inspection and tests performed during installation of switchgear; Read and understood the contents of ABB’s installation and commissioning manual.

2.3 对施工人员进行安全、技术交底

Tell the relative workers their real intentions about safety and technique.

2.4 土建交接验收

Handover inspection for civil construction

检查土建已具备安装条件,并办理交接签证

Check the condition for installation, and transact the visa of handover.

现场安装工作开始时,配电室土建工作必须已施工完毕,照明充足且已送电,室内干燥通风,门、锁齐全;所有与盘柜、电缆施工有关的前期工作已完成;室内条件达到VDE 0670标准1000/ IEC 60694部分对环境的要求,包括室内温度不低于负5摄氏度

On commencement of installation at site, the switchroom must be completely finished, provided with lighting and site electricity supply, lockable, dry and with facilities for ventilation .All the necessary preparations such as wall openings, ducts, etc.for laying of the power and control cables up to the switchgear must already be complete. Compliance with the conditions for indoor switchgear to VDE 0670 part 1000/IEC 60694, including the conditions for “minus 5 indoor” temperature class must be ensured. a. 配电室门、窗、墙壁、装饰棚应施工完毕,地面应抹平,室内干净整洁无杂物

The doors, windows, walls and decorate booth shall be completed and the floor shall be smooth, clean and free of sundries.

b.验收土建地面水平度,误差应在ABB的文件NO.XZS1-1474 A1对地面水平要求的范围内。

Check that the tolerances of the floor level do not exceed the floor level tolerances as per ABB’s document NO.XZS1-1474 A1

c. 基础型钢安装牢固可靠, 并经验收合格

Make sure that the base profiled bars are fixed and have been checked and accepted. d. 一、二次电缆进线孔符合设计要求及实际需用

The entry of primary and secondary cable shall be in accordance with design and practical requirements.

2.5 设备开箱检查

Unpacking inspection

设备开箱应有物资公司、制造厂及电仪专业人员参加

The unpacking shall be witnessed by personnel from material department of manufacturer and electric I&C team.

a. 设备型号、数量符合图纸要求

The type and quantity of equipment shall be in accordance with requirements specified by drawings.

b. 设备完好无损伤变形,附件、备件及专用工具齐全、完整;柜内安装设备型号规格符合设

计及规范

The equipments shall not be with any damage; the quality and quantity of accessories, spares and special tools shall be in accordance with requirements. The type and specification of equipments to be installed in switchboard shall be in accordance with requirements of design and specification.

c. 出厂技术资料齐全。

A full set of technical documents is required.

2.6 加工制作安装用垫铁及小滚杠

Fabrication of iron packs and rolling sticks for installation

a. 垫铁大小在40mm×50mm左右,厚度为0.5mm~2mm不等, 垫铁要平整,无尖角毛刺,数量

应满足施工要求

The iron packs shall be about 40mm×50mm and 0.5mm~2mm in length. The iron packs shall be even and smooth without burr and the quantity shall meet the requirements of construction.

b. 准备20根200mm长φ12mm圆钢

Prepare 20 pieces of φ12mm round steel in length of 200mm.

2.7 检查运输路径,确定合适的吊装方案

Check the transportation route, confirm the appropriate lifting scheme.

a. 运输道路应平坦,无障碍物

The road shall be flat without barriers.

b. 吊装口应满足盘柜尺寸要求

The size of lifting orifice shall match the corresponding switchboards.

2.8 配电室准备工作

Preparation for electric distribution room

清扫配电室地面,依据图纸用墨线打出每列柜的平齐线及端线

Clean the floor of electric distribution room, mark the base lines of each row of switchboards according to drawings.

a. 基础型钢上不得有焊渣、水泥等妨碍柜体安装的杂物

Surface of the base profiled bar shall be free of welding slag, concrete etc. foreign objects which may affect installation of the switchboard.

b. 两列柜的端线要同时打出

The base lines of the two rows of switchboards shall be marked at one time.

c. 墨线清晰,无重影,用30米钢卷尺核实与图纸要求一致

The base lines shall be clear without double trace, and shall be checked to be in accordance with drawings with a 30-meter-long steel tape.

3开关柜运输、吊装

Transportation and lifting of switchboard

3.1 开关柜运至现场后,按安装顺序吊运至配电室

The switchboards shall be lifted into the electric distribution room according to

installation sequence after arrival in the site.

a. 运输过程中车辆驾驶要平稳,封车牢固可靠,且不能损伤设备

The vehicle shall be driven reposefully during transportation, the encapsulation

shall be fast and reliable without any damage to equipments.

b. 吊装由起重工配合,统一指挥

The lifting shall be carried out by crane operators guided by supervisor.

3.2 开关小车与开关柜一体来货时,应将小车移出,放至不妨碍施工的位置

If the moveable breakers are supplied together with switchboards, they shall be

removed first to where they cannot obstruct construction.

a. 用专用运输手车移动开关小车

The moveable breakers should be moved by special tools.

b. 开关小车集中放置,罩上塑料布防护

The moveable breakers shall be collected together and covered with waterproof cloth.

3.3 用专用拖车或滚杠将开关柜体移至安装位置。开关柜摆放顺序应符合图纸要求

Move the switchboards to expected installation position by special trailer or rolling

stick.

The switchboards shall be put into place according to the designed sequence.

4 开关柜找正固定

Adjustment and fixation of the switchboards

4.1 将开关柜端部第一块盘用小滚杠和撬棍移动,使其柜边与所打墨线完全重合。再用线坠测量其

垂直度,不符合规范要求时,在柜底四角加垫铁调整,达到要求后,将柜体与基础型钢螺接固 定。

Move the first panel on the end of one row by rolling stick or crowbars, make the edges

of switchboard to superpose to the lines which have been marked on the floor. Measure the verticality with a string plummet and use iron packs for adjustment where any deviation is found. The switchboard shall not be bolt-connection onto base profiled bar until it is placed into correct position.

a. 柜体垂直度<1.5/1000H,H为柜高,应至少测量两个面

The verticality of switchboards shall be less than 1.5/1000H (H = height of the switchboards) and the height shall be measured along two faces of switchboards at least.

b. 盘柜在基础上的固定宜按厂家要求采用螺接方式,紧固件均采用镀锌件,平垫、弹簧垫齐 全;连接正确无遗漏;(当采用螺栓连接困难时也可采用焊接方式固定)

Panel shall be bolt-connected to the foundation. Fasteners shall be galvanized and plat pad and spring shall be complete. Connection is correct and to not leave out.

4.2 用上述同样方法将本列末端柜找正,但先不要牢固,在首末两柜前面中上部拉上线绳,使线绳

与柜距离在40-50mm左右,以线绳为基准,将成列柜找直。从第二面柜起,依次将每面柜找正 找直,并边连接边固定,最后去掉线绳,将末端柜重新找正,连接固定好。

Adjust the switchboard on the other end of the row according to the foresaid approach

excluding the bolt-connection. Draw a string in front of the top half of the two end switchboards, and the distance between the string and switchboards shall be kept as 40-50mm. Adjust all switchboards in the row to a beeline according to the string and adjust every individual switchboard from the second one. After adjustment finished, weld each edge of switchboards and then remove the string, and re-adjust and

bolt-connection the two end switchboards at last.

盘柜在固定之前,应检查好盘柜的一、二次电缆进线孔应该与土建预留的电缆进线孔一致对应

Before bolt-connection the each panel, it shall be verified that the cable entry in the panel matches with the cable entry slot provided in the floor of the switchgear for both power and control cables .It shall be ensured that the slot in the floor is not restricted by the panel.

a. 线绳严禁触动,一经触动,须重新核实

No contact with the string shall be allowed during adjustment otherwise it shall be readjusted.

b. 相邻两柜顶部水平度误差<2mm,成列柜顶部水平度误差<5mm

The horizontal tolerance on the top of two adjacent switchboards shall be less than 2mm and that of all switchboards in a row shall be less than 5mm.

c. 相邻两柜边不平度应<1mm,成列柜面不平度<5mm

The unevenness of the edge on two adjacent switchboards shall be less than 1mm and that between the surfaces of all switchboards in a row shall be less than 5mm. d. 柜间接缝间隙<2mm

The clearance of joint between two switchboards shall be less than 2mm.

e. 所有连盘紧固件均采用镀锌件,螺栓露扣长度一致,在2-5扣之间,连接部位及螺栓穿向

宜统一

The material of all connecting fasteners shall be galvanized and the revealed length of all bolts shall be the same and the revealed point shall be between 2-5 threads.

4.3用上述方法找正固定好第二列柜子

The second row of switchboards should be adjusted and fixed according to the foresaid approach.

4.4盘柜在基础上如采用焊接固定时,安装完成后应进行防锈、防腐处理:

盘柜在基础上安装完成后的焊接位置应补刷防锈漆,等完全干后再通刷一边与盘柜颜色相同或

相近面漆

Take antirust and anticorrosion treatment to the foundation before panel installation:

Welding position during foundation installation shall be brushed with antirust paint and be refreshed with top coat which color is the same or familiar with that of the panel after antirust paint is completely dry.

5. 母线连接

Connection of the bus bar

5.1核实母线规格、数量符合要求,两进线相序相位是否一致

Check whether the type and quantity of the bus bar meets the requirements and whether the phase of the two lines is consistent to each other.

a. 主母线及柜内分支母线制作工艺符合ABB要求

The fabrication process of bus bar and sub-bus bar shall comply with the requirements as per ABB.

b. 母线相序标示清楚正确,柜内分支母线相序排列符合规范

The phase of bus bar shall be marked correctly and legibly and the arrangement of phases of sub-bus bars shall comply with specifications.

5.2根据ABB资料要求穿接母线

Entry of the bus bar Follow ABB’s instruction manual

a. 根据成列盘柜的特点选定母线穿入的位置

Select an appropriate entry for the bus bar according to the properties of

switchboards in a row.

b. 穿母线时用力要均匀、一致、柔缓,应尽量避免损坏母线的绝缘护套及穿墙套管

The bus bar should be pulled uniformly, softly and slowly to avoid damage to the insulation sleeve.

c. 母线搭接面用白布蘸酒精擦拭干净,均匀涂抹电力复合脂

The interface of the bus bar connection shall be cleaned with white cloth sodden with alcohol and then be evenly coated with electric complex grease.

5.3母线连接

Connection of bus bar

a. 所有紧固螺栓必须是镀锌件,平垫、弹簧垫齐全

All bolts shall be galvanized and supplied together with a full set of flat and spring underlayment.

b. 应根据母线的规格型号选用螺栓,螺栓的穿向宜朝向维护侧

The bolts shall be selected in accordance to specification and type of the bus bar and their installation direction shall be such that it will be convenient for maintenance.

c. 紧固螺栓后用力矩扳手检查扭力应在ABB安装手册要求的范围内

Check the fastened bolts with a spanner to make sure that the wrest force is in the range required by the ABB installation manual.

d. 螺栓露扣长度应一致,在2-5扣之间,并按照DEP63.10.08.11-CSPC 3.2.1的要求进行传 导试验

The revealed length of all bolts shall be the same and the revealed point shall be between 2-5 threads. Perform conductivity tests as per Section 3.2.1 of DEP63.10.08.11-CSPC.

5.4紧固母线固定金具及支柱绝缘子、穿墙套管

Fastening of the anchor clamp and the insulation of the bus bar

a. 母线金具不构成闭合磁路

The anchor clamp of the bus bar shall not form a close loop.

b. 所有紧固螺栓为镀锌件,且螺栓露扣长度一致

All bolts shall be galvanized and the length of revealed thread shall be the same.

5.5加装搭接端子护套,相色应匹配,方向应统一

The connection terminals shall be covered with sleeves whose color shall match the terminals and direction shall be uniform.

5.6检查母线对地及相间距离

Check distance between the bus bar and the earth, and distance between phases respectively.

6kV母线对地及相间距离应大于100mm

The distance for 6kv bus bar shall be more than 100mm.

6. 小母线配置

Configuration for small bus bar atop the switchboard

a. 小母线选用符合厂家及设计要求

The selection of small bus bars shall be in accordance with requirements of manufacturer and design.

b. 小母线在端子排的排列应依据图纸

The arrangement of small bus bars on terminal block shall be in accordance with the drawings.

7.柜体接地检查

Inspection of earthing of the switchboards

a. 严格遵照设计接地施工。并按照DEP的要求进行传导试验

Perform the earthing according to design requirements stringently. Perform conductivity tests as per Section 3.2.1 of DEP63.10.08.11-CSPC.

b. 柜体应与基础槽钢可靠连接

The switchboard shall be connected with base channel steel reliably.

c. 装有电器可开启门的接地用软导线应将门上接地螺栓与柜体可靠连接

For switchboard equipped with moveable door, the earthing bolts on the door shall be connected with the switchboard reliably using a soft lead.

d. 接地刀接地软线压接紧固,连接可靠

The earthing switch and earthing flexible wire shall be connected rigidly. e. 小车与柜体间的接地触头应接触紧密,导通良好,通断顺序正确

小车进车时,其接地触头应比主触头先接触;出车时,接地触头比主触头后断开

The earthing feeler between the breaker and the switchboard shall contact with the earth tightly and in good condition of conduction with correct sequence of on-off. When the breakers are moving into the switchboard, its earthing feeler shall act earlier than the main feeler; When the breakers are moving out of switchboard, its earthing feeler shall be parted from the earth later than main feeler.

8. 开关柜机械部件检查

Checking for mechanical components of switchboards.

8.1开关柜找正固定好后进行的外观检查

Appearance inspection of the switchboard shall be carried out after its adjustment and fixation.

a. 柜面油漆无损伤及脱落

No damage or desquamation of paint is allowed on the surface of switchboards. b. 元件设备安装牢固,二次配线整齐美观

The components shall be installed into place tightly and the second wiring shall be in order.

c. 所有绝缘件外观应完好,无裂纹及破损

The appearance of all insulation components shall be in good condition without any crack and damage.

d. 所有紧固螺栓均齐全、完好、紧固

All earthing bolts shall be in good condition and be installed tightly.

e. 柜内照明装置齐全

The illumination equipments inside switchboards shall be in good condition without any shortage.

f. 仪表、继电器的防震设施齐全,可靠

Equipments for shockproof of instruments and relays shall be in good condition.

8.2 进出小车检查机械动作及闭锁情况,分合接地刀检查其动作、闭锁情况

The breakers shall be checked for the mechanical actions and closedown when they are moved out and located in the switchboards. Turn on and off the earthing switch and check the condition of its action and closedown.

a. 小车滚轮与轨道配合间隙均匀,小车推拉灵活轻便不摆动

The clearance between the wheels of breakers and tracks shall be uniform. The breaker shall move neatly without vibration.

b. 安全隔离板开闭灵活,无卡涩

The safety isolation board shall be opened and closed neatly without block. c. 小车在柜内试验位、工作位定位及闭锁准确可靠。小车在柜内非试验(工作)位不能合闸 The breaker shall act correctly and reliably in both test position and work position while it shall not be closed in the position not for test or work.

d. 小车进出与接地刀闭锁正确可靠,接地刀分合灵活,指示正确

The breakers shall move in and out in a correct and reliable way. The interlock of earthing switch shall be in good condition and the switch shall be turned on and off neatly with correct indication.

e. 接地刀与电缆室仓门闭锁良好可靠

The interlock of earthing switch and the door of cable room shall be in good condition.

8.3 检查同种特定类型的小车在开关仓内的互换情况

Interchanging of specific breakers of the same type in switch room

a. 相同类型的小车在其匹配的开关仓内能够互换

The breakers of the same type can be interchanged in the suited switch room.

b. 互换性能良好,小车推拉灵活,触头及二次插头接触良好

The breakers can move neatly after interchanging and the contact of feeler and plug shall in good condition.

9. 开关柜电气部件检查

Checking for electrical components of switchboards

9.1 检查各种电气触点接触紧密,通断顺序正确。

Check all electrical contact points for compactness and the correct on/off sequence. a. 一次触点上涂抹红导电脂,检查触指压痕应清晰、均匀

Daub the primary contact point with red electric tallow and check the contact impression to confirm whether they are clear and even.

b. 检查触头插入深度、备用行程及触指压力符合厂家规定

The inserted depth, spare travel and contact pressure of the feeler shall be in accordance with the regulation of manufacturer.

c. 检查动、静触头中心偏差应≤2mm

The center deviation of dynamic and static contacts shall be no more than 2mm. d. 开关辅助接点及电气联锁接点动作顺畅,接触可靠

The assistant contacts of switch and the electric interlock contacts shall work smoothly.

e. 小车与柜体间的二次回路连接插件应接触良好

The plugs of secondary loop connecting the breakers and switchboards should be in good condition.

9.2 检查带电部分对地距离

Check the distance between electriferous parts and the earth.

a. 一次部分对地距离≥100mm

The distance between the primary parts and the earth shall be no less than 100mm. b. 二次部分对地距离≥4mm

The distance between the secondary parts and the earth shall be no less than 4mm.

9.3对照施工图检查二次接线是否正确,元件配置是否符合设计要求

The secondary wiring shall be checked for correctness according to the drawing, and the configuration shall meet the requirements of design.

a. 用万用表检查接线是否正确

The wiring shall be checked with a multimeter.

b. 元器件标识齐全

All components shall have appropriate identification.

c. 元件配置符合设计要求。

The configuration of all components shall comply with the requirements of design.

9.4 如果密封箱因电缆安装影响而拆除,相邻两盘和盘底应采取措施进行密封

If the gland plate needs to be permanently removed for installation of cables, the space between the bottom of two adjacent panels and the floor shall be sealed.

参考文献:

1. GB50171-92《电气装置安装工程盘、柜及二次回路接线施工及验收规范》

GB50171-92《Code for construction and acceptance of switchboard outfit complete cubicle and secondary circuit electric equipment installation engineering》

2. DL/T5161.2002《电气装置安装工程质量检验及评定规程》

DL/T5161.2002《The quality inspection and assess regulation for electrical equipment installation》

3. 厦门ABB厂家说明书

Manufacturer’s manual of ABB

4. DEP63.10.08.11-CSPC 《电气装置与设备的现场调试与维护》

DEP63.10.08.11-CSPC 《Field commission and maintenance of electrical installations and equipment》

-

高压开关实习报告

高压开关实习报告学院机电学院姓名学号专业电气工程一高压开关设备定义高压开关设备是指在电压3千伏及以上频率50赫兹及以下的电力系统中…

-

高压开关实习报告

高压开关设备报告高压开关设备是指在电压3kV及以上频率50Hz及以下的电力系统中运行的户内和户外交流开关设备主要用于电力系统包括发…

-

高压开关柜试验报告

电力变压器试验报告试验负责人记录人审核人避雷器试验报告试验负责人记录人审核人电力电缆试验报告审核人试验负责人记录人电气设备试验报告…

-

高压开关柜出厂试验报告

高压开关柜出厂试验报告型号规格文件编号ZJ28执行标准号GB390620xx出厂编号执1执试验员审核员出厂时间年月日本报告为20x…

-

高压开关柜试验报告(完)

高压开关柜试验报告高压开关柜试验报告高压开关柜试验报告高压开关柜试验报告高压开关柜试验报告高压开关柜试验报告高压开关柜试验报告高压…

-

对供电所管理的思考电力_调研报告

对供电所管理的思考电力_调研报告通过对清坪供电所xxxx抄表员所管辖的1xxxx台区216xxxx用电户中的xxxx台区3xxxx…

-

电力拖动调研报告

基于任务驱动式中职电力拖动控制线路的教学改变旧的办学观念创新以学生为主体的办学方法是对中等职业教育机电专业实施教学改革的指导思想探…

-

xx供电公司供电服务调研报告

河南省电力公司洛阳供电公司供电服务效能监察调研报告近年来市公司在国家电网公司和省公司的正确领导下在市委市政府电监会等有关部门的支持…

-

绿色电力 调查报告

绿色电力重走长征路调查报告班级通信1102姓名傅慧华学号20xx03010207第一部分调研概述一背景随着经济建设及改革开放的进一…

-

区内电厂调研报告

区内电厂调研报告一区内电厂的基本情况目前销售部业务六部管辖的区内电厂主要包括银川及以南的13家电厂各电厂的基本情况如下大坝电厂全称…

-

高压开关实习报告

高压开关实习报告学院机电学院姓名学号专业电气工程一高压开关设备定义高压开关设备是指在电压3千伏及以上频率50赫兹及以下的电力系统中…