华北电力大学数控铣床实验报告

华北电力大学

实验报告

|

|

实训项目 数控铣床的操作和编程

课程名称专业综合实验

|

|

专业班级: 学生姓名:

学 号: 成 绩:

指导教师: 实验日期:

1、目的与要求

目的: 1)、了解数控铣床的结构和工作原理;

2)、掌握数控铣床的编程;

3)、掌握数控铣床的手动操作;

4)、掌握数控铣床的刀具补偿输入、程序自动运行。

要求:在规定的课程周期内:

1)、熟悉铣床本体、CNC、伺服单元、PLC、面板等部件的结构、原理、作用。

2)、掌握手动编程各种指令的意义功能;在掌握数控铣削加工工艺的基础上,根据加工工艺,编写指定零件的加工程序。

3)、能够熟练操作数控铣床。

4)、独立完成数控铣床的对刀,程序编制、录入,加工出合格的零件。

5)、按课程要求编写相应的实训报告。

2、实验报告内容要求:

1)简述数控铣床的结构和工作原理,数控铣削的加工过程;

2)指定零件的加工工艺,根据加工工艺编写零件的加工程序;

3)简述数控机床的操作过程,试切对刀的操作要点;

4)加工出的零件的照片。

5)个人总结及心得体会;

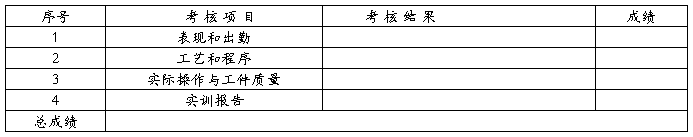

成绩评定表:

指导教师:

年 月 日

一、简述数控铣床的结构和工作原理,数控铣削的加工过程

1. 数控铣床的组成 :数控铣床是由数控程序及存储介质、输入输出设备、计算机数控装置、伺服系统、机床本体组成。

2. 数控铣床的工作原理:数控铣床是一种高度自动化的机床,在加工工艺与加工表面形成方法上,与普通机床是基本相同的,最根本的不同在于实现自动化控制的原理与方法上。数控铣床是用数字化的信息来实现自动化控制的,将与加工零件有关的信息—工件与刀具相对运动轨迹的尺寸参数(进给执行部件的进给尺寸),切削加工的工艺参数(主运动和进给运动的速度、切削深度等),以及各种辅助操作(主运动变速、刀具更换、冷却润滑液关停、工件夹紧松开等)等加工信息—用规定的文字、数字和符号组成的代码,按一定的格式编写成加工程序单,将加工程序通过控制介质输入到数控装置中,由数控装置经过分析处理后,发出各种与加工程序相对应的信号和指令控制机床进行自动加工。数控铣床的数字控制的原理与过程通过下述的数控铣床组成可得到更明确的说明。

3. 数控铣削的加工过程:

① 首先根据零件加工图样进行工艺分析,确定加工方案、工艺参数和位移数据。

② 用规定的程序代码和格式规则编写零件加工程序单;或用自动编程软件进行CAD/CAM工作,直接生成零件的加工程序文件。

③ 程序的输入和输出。手工编写的程序通过数控机床的操作面板输入,软件生成的程序通过传输通讯技术直接传输到机床。

④ 将输入的数控单元的加工程序进行试运行和刀具路径模拟等。

⑤ 通过机床的正确操作,运行程序,完成零件的加工。

二、数控机床的操作过程,试切对刀的操作要点

1. 手工编程操作

将编制的加工程序输入数控系统,具体的操作方法是:先通过机械操作面板启动数控机床,接着由CRT/MDI面板输入加工程序,然后运行加工程序。

a、启动数控机床操作

① 机床启动按钮ON

② 程序锁定按钮OFF

b、编辑操作

① 选择MDI方式或EDIT方式

② 按(PRGRM)健

③ 输入程序名:键入程序地址符、程序号字符后按(INSRT)键。

④ 键入程序段

⑤ 键入程序段号、操作指令代码后按(INPUT)键。

c、运行程序操作

① 程序锁定按钮ON

② 选择自动循环方式

2. 调用程序操作

调用已储存在数控系统中的加工程序,具体的操作方法先通过机械操作面板启动数控机床,接着调用系统内的加工程序,然后运行程序。

a、启动数控机床操作

① 机床启动按钮ON

② 程序锁定按钮OFF

b、调用程序操作

① 选择MDI方式或EDIT方式

② 按(PRGRM)键

③ 调用程序 键入程序地址符、程序号字符后按(INPUT)键。

c、运行程序操作

① 程序锁定按钮ON

② 选择自动循环方式

③ 按自动循环按钮

3. 试切对刀的操作要点:先将工件和刀具装夹完毕,驱动主轴旋转,移动刀具试切工件的右端面,保持Z坐标不变X轴移动刀具离开工件,在相应刀具参数中Z的刀补中输入Z0,系统会自动将此时刀具的Z坐标减去刚才输入的数值,即得工件坐标系Z原点的位置。再移动刀架至工件试切一段外圆。然后保持X坐标不变Z轴移动刀具离开工件,测量出该段外圆的直径,将其输入到相应的刀具参数中X的刀补中,系统会自动用刀具当前X坐标减去试切出的那段外圆直径,即得到工件坐标系X原点的位置。

三、零件的加工程序:

%

O1002;

G54 G40 G80 G17 G90 G49;

M3 S1000;

G00 Z5.0 F200.0;

G00 X0.0 Y0.0

G00 X-50.0 Y50.0

G01 Z-2.0

G01 X-47.0

G01 X-50.0 Y47.0

G01 Y50.0

G01 X-44.0

G01 X-50.0 Y44.0

G01 Y50.0

G01 X-41.0

G01 X-50.0 Y41.0

G01 Y50.0

G01 X-38.0

G01 X-50.0 Y38.0

G01 Y50.0

G01 X-35.0

G01 X-50.0 Y35.0

G01 Y50.0

G01 X-32.0

G01 X-50.0 Y32.0

G01 Y50.0

G01 X-29.0

G01 X-50.0 Y29.0

G01 Y50.0

G01 X-26.0

G01 X-50.0 Y26.0

G01 Y50.0

G01 X-23.0

G01 X-50.0 Y23.0

G01 Y50.0

G01 X-20.0

G01 X-50.0 Y20.0

G01 Y50.0

G01 X-17.0

G01 X-50.0 Y17.0

G01 Y50.0

G01 X-14.0

G01 X-50.0 Y14.0

G01 Y50.0

G01 X-11.0

G01 X-50.0 Y11.0

G01 Y50.0

G01 X-8.0

G01 X-50.0 Y8.0

G01 Y50.0

G00 X-50.0 Y50.0

G01 Z-4.0

G01 X-47.0

G01 X-50.0 Y47.0

G01 Y50.0

G01 X-44.0

G01 X-50.0 Y44.0

G01 Y50.0

G01 X-41.0

G01 X-50.0 Y41.0

G01 Y50.0

G01 X-38.0

G01 X-50.0 Y38.0

G01 Y50.0

G01 X-35.0

G01 X-50.0 Y35.0

G01 Y50.0

G01 X-32.0

G01 X-50.0 Y32.0

G01 Y50.0

G01 X-29.0

G01 X-50.0 Y29.0

G01 Y50.0

G01 X-26.0

G01 X-50.0 Y26.0

G01 Y50.0

G01 X-23.0

G01 X-50.0 Y23.0

G01 Y50.0

G01 X-20.0

G01 X-50.0 Y20.0

G01 Y50.0

G01 X-17.0

G01 X-50.0 Y17.0

G01 Y50.0

G01 X-14.0

G01 X-50.0 Y14.0

G01 Y50.0

G01 X-11.0

G01 X-50.0 Y11.0

G01 Y50.0

G01 X-8.0

G01 X-50.0 Y8.0

G01 Y50.0

G00 X-50.0 Y50.0

G01 Z-5.0

G01 X-47.0

G01 X-50.0 Y47.0

G01 Y50.0

G01 X-44.0

G01 X-50.0 Y44.0

G01 Y50.0

G01 X-41.0

G01 X-50.0 Y41.0

G01 Y50.0

G01 X-38.0

G01 X-50.0 Y38.0

G01 Y50.0

G01 X-35.0

G01 X-50.0 Y35.0

G01 Y50.0

G01 X-32.0

G01 X-50.0 Y32.0

G01 Y50.0

G01 X-29.0

G01 X-50.0 Y29.0

G01 Y50.0

G01 X-26.0

G01 X-50.0 Y26.0

G01 Y50.0

G01 X-23.0

G01 X-50.0 Y23.0

G01 Y50.0

G01 X-20.0

G01 X-50.0 Y20.0

G01 Y50.0

G01 X-17.0

G01 X-50.0 Y17.0

G01 Y50.0

G01 X-14.0

G01 X-50.0 Y14.0

G01 Y50.0

G01 X-11.0

G01 X-50.0 Y11.0

G01 Y50.0

G01 X-8.0

G01 X-50.0 Y8.0

G01 Y50.0

G00 Z5.0

G00 X50.0 Y50.0

G01 Z-2.0

G01 X47.0

G01 X50.0 Y47.0

G01 Y50.0

G01 X44.0

G01 X50.0 Y44.0

G01 Y50.0

G01 X41.0

G01 X50.0 Y41.0

G01 Y50.0

G01 X38.0

G01 X50.0 Y38.0

G01 Y50.0

G01 X35.0

G01 X50.0 Y35.0

G01 Y50.0

G01 X32.0

G01 X50.0 Y32.0

G01 Y50.0

G01 X29.0

G01 X50.0 Y29.0

G01 Y50.0

G01 X26.0

G01 X50.0 Y26.0

G01 Y50.0

G01 X23.0

G01 X50.0 Y23.0

G01 Y50.0

G01 X20.0

G01 X50.0 Y20.0

G01 Y50.0

G01 X17.0

G01 X50.0 Y17.0

G01 Y50.0

G01 X14.0

G01 X50.0 Y14.0

G01 Y50.0

G01 X11.0

G01 X50.0 Y11.0

G01 Y50.0

G01 X8.0

G01 X50.0 Y8.0

G01 Y50.0

G00 X50.0 Y50.0

G01 Z-4.0

G01 X47.0

G01 X50.0 Y47.0

G01 Y50.0

G01 X44.0

G01 X50.0 Y44.0

G01 Y50.0

G01 X41.0

G01 X50.0 Y41.0

G01 Y50.0

G01 X38.0

G01 X50.0 Y38.0

G01 Y50.0

G01 X35.0

G01 X50.0 Y35.0

G01 Y50.0

G01 X32.0

G01 X50.0 Y32.0

G01 Y50.0

G01 X29.0

G01 X50.0 Y29.0

G01 Y50.0

G01 X26.0

G01 X50.0 Y26.0

G01 Y50.0

G01 X23.0

G01 X50.0 Y23.0

G01 Y50.0

G01 X20.0

G01 X50.0 Y20.0

G01 Y50.0

G01 X17.0

G01 X50.0 Y17.0

G01 Y50.0

G01 X14.0

G01 X50.0 Y14.0

G01 Y50.0

G01 X11.0

G01 X50.0 Y11.0

G01 Y50.0

G01 X8.0

G01 X50.0 Y8.0

G01 Y50.0

G00 X50.0 Y50.0

G01 Z-5.0

G01 X47.0

G01 X50.0 Y47.0

G01 Y50.0

G01 X44.0

G01 X50.0 Y44.0

G01 Y50.0

G01 X41.0

G01 X50.0 Y41.0

G01 Y50.0

G01 X38.0

G01 X50.0 Y38.0

G01 Y50.0

G01 X35.0

G01 X50.0 Y35.0

G01 Y50.0

G01 X32.0

G01 X50.0 Y32.0

G01 Y50.0

G01 X29.0

G01 X50.0 Y29.0

G01 Y50.0

G01 X26.0

G01 X50.0 Y26.0

G01 Y50.0

G01 X23.0

G01 X50.0 Y23.0

G01 Y50.0

G01 X20.0

G01 X50.0 Y20.0

G01 Y50.0

G01 X17.0

G01 X50.0 Y17.0

G01 Y50.0

G01 X14.0

G01 X50.0 Y14.0

G01 Y50.0

G01 X11.0

G01 X50.0 Y11.0

G01 Y50.0

G01 X8.0

G01 X50.0 Y8.0

G01 Y50.0

G00 Z5.0

G00 X50.0 Y-50.0

G01 Z-2.0

G01 X47.0

G01 X50.0 Y-47.0

G01 Y-50.0

G01 X44.0

G01 X50.0 Y-44.0

G01 Y-50.0

G01 X41.0

G01 X50.0 Y-41.0

G01 Y-50.0

G01 X38.0

G01 X50.0 Y-38.0

G01 Y-50.0

G01 X35.0

G01 X50.0 Y-35.0

G01 Y-50.0

G01 X32.0

G01 X50.0 Y-32.0

G01 Y-50.0

G01 X29.0

G01 X50.0 Y-29.0

G01 Y-50.0

G01 X26.0

G01 X50.0 Y-26.0

G01 Y-50.0

G01 X23.0

G01 X50.0 Y-23.0

G01 Y-50.0

G01 X20.0

G01 X50.0 Y-20.0

G01 Y-50.0

G01 X17.0

G01 X50.0 Y-17.0

G01 Y-50.0

G01 X14.0

G01 X50.0 Y-14.0

G01 Y-50.0

G01 X11.0

G01 X50.0 Y-11.0

G01 Y-50.0

G01 X8.0

G01 X50.0 Y-8.0

G01 Y-50.0

G00 X50.0 Y-50.0

G01 Z-4.0

G01 X47.0

G01 X50.0 Y-47.0

G01 Y-50.0

G01 X44.0

G01 X50.0 Y-44.0

G01 Y-50.0

G01 X41.0

G01 X50.0 Y-41.0

G01 Y-50.0

G01 X38.0

G01 X50.0 Y-38.0

G01 Y-50.0

G01 X35.0

G01 X50.0 Y-35.0

G01 Y-50.0

G01 X32.0

G01 X50.0 Y-32.0

G01 Y-50.0

G01 X29.0

G01 X50.0 Y-29.0

G01 Y-50.0

G01 X26.0

G01 X50.0 Y-26.0

G01 Y-50.0

G01 X23.0

G01 X50.0 Y-23.0

G01 Y-50.0

G01 X20.0

G01 X50.0 Y-20.0

G01 Y-50.0

G01 X17.0

G01 X50.0 Y-17.0

G01 Y-50.0

G01 X14.0

G01 X50.0 Y-14.0

G01 Y-50.0

G01 X11.0

G01 X50.0 Y-11.0

G01 Y-50.0

G01 X8.0

G01 X50.0 Y-8.0

G01 Y-50.0

G00 X50.0 Y-50.0

G01 Z-5.0

G01 X47.0

G01 X50.0 Y-47.0

G01 Y-50.0

G01 X44.0

G01 X50.0 Y-44.0

G01 Y-50.0

G01 X41.0

G01 X50.0 Y-41.0

G01 Y-50.0

G01 X38.0

G01 X50.0 Y-38.0

G01 Y-50.0

G01 X35.0

G01 X50.0 Y-35.0

G01 Y-50.0

G01 X32.0

G01 X50.0 Y-32.0

G01 Y-50.0

G01 X29.0

G01 X50.0 Y-29.0

G01 Y-50.0

G01 X26.0

G01 X50.0 Y-26.0

G01 Y-50.0

G01 X23.0

G01 X50.0 Y-23.0

G01 Y-50.0

G01 X20.0

G01 X50.0 Y-20.0

G01 Y-50.0

G01 X17.0

G01 X50.0 Y-17.0

G01 Y-50.0

G01 X14.0

G01 X50.0 Y-14.0

G01 Y-50.0

G01 X11.0

G01 X50.0 Y-11.0

G01 Y-50.0

G01 X8.0

G01 X50.0 Y-8.0

G01 Y-50.0

G00 Z5.0

G00 X-50.0 Y-50.0

G01 Z-2.0

G01 X-47.0

G01 X-50.0 Y-47.0

G01 Y-50.0

G01 X-44.0

G01 X-50.0 Y-44.0

G01 Y-50.0

G01 X-41.0

G01 X-50.0 Y-41.0

G01 Y-50.0

G01 X-38.0

G01 X-50.0 Y-38.0

G01 Y-50.0

G01 X-35.0

G01 X-50.0 Y-35.0

G01 Y-50.0

G01 X-32.0

G01 X-50.0 Y-32.0

G01 Y-50.0

G01 X-29.0

G01 X-50.0 Y-29.0

G01 Y-50.0

G01 X-26.0

G01 X-50.0 Y-26.0

G01 Y-50.0

G01 X-23.0

G01 X-50.0 Y-23.0

G01 Y-50.0

G01 X-20.0

G01 X-50.0 Y-20.0

G01 Y-50.0

G01 X-17.0

G01 X-50.0 Y-17.0

G01 Y-50.0

G01 X-14.0

G01 X-50.0 Y-14.0

G01 Y-50.0

G01 X-11.0

G01 X-50.0 Y-11.0

G01 Y-50.0

G01 X-8.0

G01 X-50.0 Y-8.0

G01 Y-50.0

G00 X-50.0 Y-50.0

G01 Z-4.0

G01 X-47.0

G01 X-50.0 Y-47.0

G01 Y-50.0

G01 X-44.0

G01 X-50.0 Y-44.0

G01 Y-50.0

G01 X-41.0

G01 X-50.0 Y-41.0

G01 Y-50.0

G01 X-38.0

G01 X-50.0 Y-38.0

G01 Y-50.0

G01 X-35.0

G01 X-50.0 Y-35.0

G01 Y-50.0

G01 X-32.0

G01 X-50.0 Y-32.0

G01 Y-50.0

G01 X-29.0

G01 X-50.0 Y-29.0

G01 Y-50.0

G01 X-26.0

G01 X-50.0 Y-26.0

G01 Y-50.0

G01 X-23.0

G01 X-50.0 Y-23.0

G01 Y-50.0

G01 X-20.0

G01 X-50.0 Y-20.0

G01 Y-50.0

G01 X-17.0

G01 X-50.0 Y-17.0

G01 Y-50.0

G01 X-14.0

G01 X-50.0 Y-14.0

G01 Y-50.0

G01 X-11.0

G01 X-50.0 Y-11.0

G01 Y-50.0

G01 X-8.0

G01 X-50.0 Y-8.0

G01 Y-50.0

G00 X-50.0 Y-50.0

G01 Z-5.0

G01 X-47.0

G01 X-50.0 Y-47.0

G01 Y-50.0

G01 X-44.0

G01 X-50.0 Y-44.0

G01 Y-50.0

G01 X-41.0

G01 X-50.0 Y-41.0

G01 Y-50.0

G01 X-38.0

G01 X-50.0 Y-38.0

G01 Y-50.0

G01 X-35.0

G01 X-50.0 Y-35.0

G01 Y-50.0

G01 X-32.0

G01 X-50.0 Y-32.0

G01 Y-50.0

G01 X-29.0

G01 X-50.0 Y-29.0

G01 Y-50.0

G01 X-26.0

G01 X-50.0 Y-26.0

G01 Y-50.0

G01 X-23.0

G01 X-50.0 Y-23.0

G01 Y-50.0

G01 X-20.0

G01 X-50.0 Y-20.0

G01 Y-50.0

G01 X-17.0

G01 X-50.0 Y-17.0

G01 Y-50.0

G01 X-14.0

G01 X-50.0 Y-14.0

G01 Y-50.0

G01 X-11.0

G01 X-50.0 Y-11.0

G01 Y-50.0

G01 X-8.0

G01 X-50.0 Y-8.0

G01 Y-50.0

G00 Z5.0

G00 X-57.0 Y0.0

G01 Z-5.0

G01 X0.0 Y57.0

G01 X57.0 Y0.0

G01 X0.0 Y-57.0

G01 X-57.0 Y0.0

G00 Z5.0

G00 X-30.0 Y0.0

G01 Z-2.0

G01 Y3.0

G17 G02 X-30.0 Y3.0 I0.0 J-3.0

G00 X-30.0 Y0.0

G01 Z-4.0

G01 Y3.0

G17 G02 X-30.0 Y3.0 I0.0 J-3.0

G00 X-30.0 Y0.0

G01 Z-5.0

G01 Y3.0

G17 G02 X-30.0 Y3.0 I0.0 J-3.0

G00 Z5.0

G00 X0.0 Y0.0

G01 Z-2.0

G01 Y3.0

G17 G02 X0.0 Y3.0 I0.0 J-3.0

G00 X0.0 Y0.0

G01 Z-4.0

G01 Y3.0

G17 G02 X0.0 Y3.0 I0.0 J-3.0

G00 X0.0 Y0.0

G01 Z-5.0

G01 Y3.0

G17 G02 X0.0 Y3.0 I0.0 J-3.0

G00 Z5.0

G00 X30.0 Y0.0

G01 Z-2.0

G01 Y3.0

G17 G02 X30.0 Y3.0 I0.0 J-3.0

G00 X30.0 Y0.0

G01 Z-4.0

G01 Y3.0

G17 G02 X30.0 Y3.0 I0.0 J-3.0

G00 X30.0 Y0.0

G01 Z-5.0

G01 Y3.0

G17 G02 X30.0 Y3.0 I0.0 J-3.0

G00 Z5.0

G00 X48.5 Y50.0

G01 Z-2.0

G01 X35.1 Y36.5

G03 X36.5 Y35.1 R1.0

G01 X50.0 Y48.5

G00 Z5.0

G00 X48.5 Y-50.0

G01 Z-2.0

G01 X35.1 Y-36.5

G02 X36.5 Y-35.1 R1.0

G01 X50.0 Y-48.5

G00 Z5.0

G00 X-48.5 Y-50.0

G01 Z-2.0

G01 X-35.1 Y-36.5

G03 X-36.5 Y-35.1 R1.0

G01 X-50.0 Y-48.5

G00 Z5.0

G00 X-48.5 Y50.0

G01 Z-2.0

G01 X-35.1 Y36.5

G02 X-36.5 Y35.1 R1.0

G01 X-50.0 Y48.5

G00 Z50.0;

X0.0 Y0.0;

M5;

M30;

%

四、加工出的零件的照片

-

东南大学高等数学实验报告

高等数学数学实验报告实验人员:院(系)_______________学号________姓名实验地点:计算机中心机房实验一一、实验…

- 大学数学实验报告----素数

-

北京科技大学数学实验报告---第7次

数学实验报告实验名称matlab学院专业班级姓名学号20xx年6月一实验目的通过课后习题的练习掌握利用matlab进行概率运算和数…

-

重庆大学数学实验实验报告(参考)

重庆大学学生实验报告实验课程名称数学实验开课实验室学院年级专业班学生姓名学号开课时间学期数学与统计学院制开课学院实验室数学与统计D…

-

数学实验报告

西安交通大学数学实验报告高等数学实验报告MATLAB实验操作报告同组人髙加西20xx年04月10日电气工程学院电气工程与自动化专业…

-

数控铣床实训报告

实训报告系(院、校区):学生姓名:学号:专业:题目:模具数控加工技术实训报告指导教师:职称:20xx年x月x日模具数控加工技术实训…

-

数控机床实验报告简答题

1.数控车床由哪几部分组成?数控车床由数控装置、床身、主轴箱、刀架进给系统、尾座、液压系统、冷却系统、润滑系统、排屑器等部分组成。…

-

数控机床实验报告

数实控验报班级姓名:学号:机告床书《》实验一:《宇航数控加工仿真系统》功能熟悉实验二:数控车床编程与仿真操作1.数控车床由哪几部分…

-

数控铣床编程与操作实验报告

实验四数控铣床编程与操作实验报告班级学号姓名成绩一、实验目的二、实验仪器与设备三、实验内容简述1、了解数控铣床的结构和常用功能指令…

-

小型数控铣床操作实验报告

实验报告实验内容:小型数控铣床操作实验20xx年x月x日院系:物科院班级:085学号:07080518姓名:陈实一、实验目的1、熟…