水尺报告范本

Total pages: 6

M/V“SEA BAISEN”

Draft Survey Supervision on Thailand Tapioca Chips

at Port of Lianyungang, P.R. China

ON THE 11TH & 5TH DEC 20##

1. ORDER:

At the request of Sun Alliance Insurance (China) Limited, and on behalf of the cargo Insurer of M/V “SEA BAISEN”, we did, on the 11th Dec. 2012, attend on board the vessel whilst she was berthed alongside at the berth No.61 of Dongtai Stevedoring Company, Port of Lianyungang, P. R. China, for the purpose of carrying out the Draft Survey Supervision on Thailand Tapioca Chips.

We hereby report as follows:

2. SHIP’S PARTICULAR:

1) Name of Vessel : M/V “SEA BAISEN”

2) Port of Registry : PANAMA

3) Official / IMO No. : 25595-98-A/ 9125815

4) Owners : XIN ZHEN HAI SHIPPING CO.,LTD

5) Kind of Ship : General Cargo

6) Gross/Net Tonnage : 17,172 / 9,770

7) Deadweight (Summer) : 26,613 MT

8) LOA/Breadth/Depth (M) : 172 / 26 /13.4

3. CARGO UNDER SURVEY:

Total 3 B/L、21,145.374 MT of Thailand Tapioca Chips on board was to be discharged at Lianyungang port, China.

B/L No. : SB/CH-01

Shipper : Thong Tapioca(1999)Co.,Ltd

Consignee : To order

Notify : Jinyimeng Group Co., Ltd

Loading Port : Kohsichang Port, Thailand

Discharge Port : Lianyungang, China

Commodity : Thailand Tapioca Chips

Gross weight : 9,585.429 MT

B/L No. : SB/CH-02

Shipper : Sa Watpaiboon Tapioca Ltd

Consignee : To order

Notify : Jinyimeng Group Co., Ltd

Loading Port : Kohsichang Port, Thailand

Discharge Port : Lianyungang, China

Commodity : Thailand Tapioca Chips

Gross weight : 10,222.750 MT

B/L No. : SB/CH-03

Shipper : Thong Tapioca(1999)Co.,Ltd

Consignee : To order

Notify : Jinyimeng Group Co., Ltd

Loading Port : Kohsichang Port, Thailand

Discharge Port : Lianyungang, China

Commodity : Thailand Tapioca Chips

Gross weight : 1,337.195 M

4. GENERAL INFORMATION:

We attended on board of the vessel at 1200 hours on the 11th December 2012, after interviewed with Captain and Chief Officer. We obtained the following information from the statement of them:

1). M/V “SEA BAISEN” sailed from the loading port –Kohsichang Port, Thailand with total 21,145.374 MT of Tapioca Chips in bulk on board, and bound for the discharging port of Lianyungang, China.

2). The vessel arrived at the anchorage of Lianyungang port at 0620 hours on 10th December 2012. Pilot embarked on board at 0905 hours on 11th December 2012, and the vessel was finally completed berthing alongside the No.61berth of Dongtai Stevedoring Company, Lianyungang port at 1110 hours on the same day.

3). The stowage plan was shown as follows:

Hold No. Description Quantity

1 Thailand Chips in bulk 2,722.75 MT

2 Thailand Chips in bulk 4,550 MT

3 Thailand Chips in bulk 4,450MT

4 Thailand Chips in bulk 4,622.624 MT

5 Thailand Chips in bulk 4,800 MT

----------------------------------------------------------------------------------------------------------

Total: Tapioca Chips in bulk 21,145.374 MT

5. DRAFT SURVEY SUPERVISION:

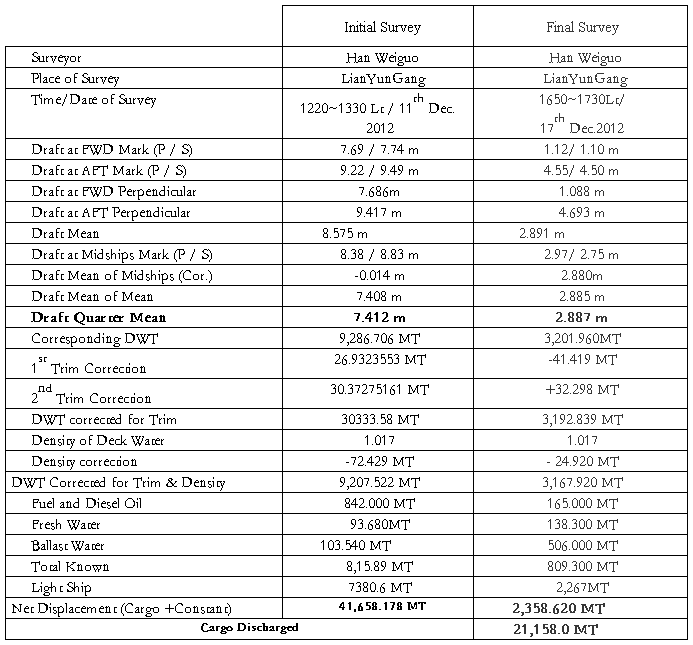

Prior to discharging the cargo of Tapioca Chips, from 1220 hours to 1330 hours on 11th December 2012, the chief officer of M/V “SEA BAISEN” jointly with the CCIC officers on behalf of consignee, carried out the initial draft survey, we also attended at the spot for inspecting & supervising the whole process of Initial draft survey.

The cargo discharging from the holds commenced at 1400 hours on 11th December 2012.

The discharging operation of Thailand Tapioca Chips completed at 1630 hours on 17th December 2012.

From 1650 hours to 1730 hours on 20th December2012, the chief officer of M/V “SEA BAISEN” jointly with the CCIC officers - on behalf of consignee, carried out the final draft survey, we also attended at the spot for inspecting & supervising the whole process of draft survey.

As per the initial & final draft calculation from our side, we found total 6,033.012 MT of Tapioca Chips had been discharged from the holds No.1~5, which was about 1.222 MT (0.002%) of cargo More than the figure indicated on the Bs/L (21,145.374MT).

The detail of the initial & final draft survey conducted by us was shown as follows:

DRAFT SURVEY REPORT

Vessel Name : M/V “SEA BAISEN”

Sea Condition : Smooth

Commodity : Thailand Tapioca Chips

Quantity in B/L : 21,145.374 MT

Light Ship : 7380.6

LBP : 164 M

LBM : 85.20 M

Length between FP & Marks : - 0.55 M

Length between AP & Marks : +2.40 M

Length between Midships & Marks : 0.5 M

Trim (Initial / Final) : 1.64/ 3.694

LCF (Initial / Final) : -2.13 / -0.83

TPC (Initial / Final) : 14.6 / 12.45

MTC 1 (Initial / Final) : 86.06 / 58.34

MTC 2 (Initial / Final) : 77.89 / 53.87

DMTC (Initial / Final) : 8.17 / 4.47

6. DISCREPANCY AND COMMENTS:

As per the draft calculation from the CCIC Surveyor, we got to know that the total cargo weight was about 6,031.000 MT had been discharged from the holds No.1~5, which was about 0.79 MT (0.001 %) of cargo SHORTAGE than the figure indicated on the Bs/L (21,145.374 MT). The figure was very near to our survey figure.

The C/O did not calculate the final draft figure. There was no any claim about the cargo quantity and quality.

The M/V “SEA BAISEN” sailed from Lianyungang port at 1920 hours on 17th December 2012.

7. FINALLY: - This Report is issued without prejudice to the question of liability, and the facts contained in this report are, to the best of our knowledge and belief, TRUE AND CORRECT.

Attending Surveyor: Han Weiguo G. Manager: Fang Weiguo

(Signature) (Signature)

Date of Report: 18th December 2012

ATTACHMENTS:

1). Mate’s Receipt 1 Page

2). Stowage Plan 1 Page

3). Draft Report 2 Pages

第二篇:内审报告范本

一.审核报告内容:

20xx年元月19日在****会议室于上午9:30分召开首次会议后开始进行第二次内部质量体系审核。由公司内部质量审核员组成的审核组在***老师和审核组长指导下分别对业务部、综合部、主管、调度、信息员、计量员、检验员、采购、备件库、仓库仔细进行了验证质量体系运行的有效性和符合性为目的的内部质量审核。经过一天时间寻找出存在的一些问题,总计不合格项5项,业务部4项,综合部1项,其中信息员所负责的要素——文件和资料控制3项,安装班1项,备件库1项,下面对各个部门和岗位在审核中发现的问题进行汇总分析:

一. 业务部:

业务部所涉及的要素主要有4.3 4.5 4.7 4.8 4.9 4.10 4.12 4.13 4.15 4.16 4.17 4.18 4.19 4.20 业务部从整个审核情况来看,各要素负责人对程序接口较为模糊,对质量体系建立的整体概念不是很清晰,主要存在如下问题:

1. 信息员:

从岗位职能分布图和质量职能分布图中看出,信息员所负责的要素有4.5 4.16 4.14 4.204个要素,但实际中信息员仅负责前两个要素,事实上存在着不符合性。

A. 由信息员所控制的文件和资料,在整个质量体系是最为重要的一个部分,但在这方面相对来说做得较差,受控文件清单混乱、分类模糊。

B. 文件发放审批表和文件发放回收台帐日期和范围不相符合,还有份文件传阅单在文件生效之后填写记录的情况,整个控制显得勉强,效果性较差。

C. 文件传阅单和文件发放登记台帐混用。

D. 三层次文件编号重复、失控。

E. 质量记录没有按规定日期进行归档,填写的质量记录标识卡没有经过审核。

2. 调度:

调度在质量体系中所负责的4.3 4,9 4.13 4.19 等要素中较符合要求,但也存在部分问题:

A. 在对人员进行控制上还达不到要求,人员上岗证台帐由于理解不对只登记了作废上

岗证台帐。

B. 在设备和工具的控制上达不到要求,在设备和工具的概念上由于对三层次文件缺乏了解还未区分开。

二. 综合部

1.采购:

采购是综合部控制的一个重点,采购产品的好坏直接影响到我们的服务质量,在以前的服务过程中出现过由于采购电源线不符合要求而返工的情况发生。采购要素在上次审核中较合符要求,但这次内审没有明显的进步,在选择合格的分承包方的档案中,仍然不全,缺少国家、行业质量标准、采购的物资和质量体系要求的质量标准不相符合;对部分的采购产品的使用情况没有进行评价和验证。

2.计量员:

计量器具的控制较符合标准和程序文件的要求,存在的不完善地方具体有以下方面:

A. 在库房的温度、湿度计没有按规定进行检验。

B. 送检的单位资格证和公章不相符合。

3. 检验员:

检验员在物资和备件的检验控制还停留在以前的表面,没有真正的运用检验过程和结果为采购的物资和备件做为部分依据,具体的检验依据显得较为粗糙,相应的质量记录也无法体现检验结果是否符合要求。

4. 安装班和维修班:

安装班和维修班作为服务过程的直接体现者,我们的服务是否优秀、服务过程是否是受到控制,都在用户家通过服务人员直接体现出来,在本次内审中由于时间关系,没来得及安排上门过程审核,仅在现场发现有如下几方面问题:

A. 关键、特殊工序的控制中,本公司制定了相应的关键、特殊工序作业指导书,但对其执行过程中的质量记录不完善。

B. 通过给职工发放、学习了产品搬运指导书、在产品的搬运过程中符合要求,但某些

职工由于原来的习惯一时还未纠正,希望在以后过程中能够尽快纠正和完善。

C. 由于对安装班和维修班发放的《****职工配备手册》属于受控文件,在职工中有些对其保管不符合程序文件要求不够,在其上面有些部分不应该的记录,在此方面有些欠缺。

D. 《****职工配备手册》部分内容直接由程序文件复印缩小印制,不符合程序文件要求,所以该手册必须回收重新配备。

5. 内审结论:

通过这次内审情况来看,我们整个质量体系已经建立并运行,针对上次不合格项,通过一年多运行,整个质量体系在不断的完善和进步,比上次有了质的改变;但由于时间较为短促,不断的改变过程有的要素显得有些混乱;而且由于质量体系要求有所提高,要素负责人显得有些吃力,在对标准理解和程序文件整体协调和全面理解掌握上还未完全达到要求,在采购、计量、调度、备件管理等岗位做得相对较为完善外,信息员显得有些混乱不足,在接下来是一个重点纠正对象,在安装班和维修班的控制情况反映:由于面临春节,人员回家较多,改进措施不能在短时间宣贯到位,应该做一些调整。

面临外审时间不多,难度较大,希望质量体系涉及的全部岗位和人员能够同心协力,为外审做好准备,保证一次通过外审。

6. 不合格项的关闭步骤:

1. 由部门负责人确认不合格项。

2. 由公司内审员协助各要素负责人分协不合格原因。

3. 由公司内审员帮助要素负素人制定纠正措施。

4. 由各不合格项部门负责人制定纠正措施计划上交。

5. 由公司内审员对纠正措施有效性进行验证和监督完成情况。

6. 由公司经理和公司内审员负责继续建立并保持质量体系实施执行过程。

7. 由管理者代表负责监督整个质量体系实施性和效果性。

-

水尺报告范本

RSArefSDCCS120xx160STotalpages6THTH1ORDERAttherequestofSunAllianceInsurance…

-

20xx年水尺市场分析报告

中国产业洞察网20xx年9月份第一中国产业洞察网研究员对市场调查报告的解读第二什么样的市场调查报告才是合格的第三什么样的市场调查报…

-

20xx-20xx年中国链式水尺市场分析预测及战略咨询报告

20xx20xx年中国链式水尺市场分析预测及战略咨询报告艾凯咨询网艾凯咨询网什么是行业研究报告行业研究是通过深入研究某一行业发展动…

-

水文学实习报告二 文档

水利专业平赴浏阳双江口水文站学实习报告一、目的与要求水利水电工程的规划、设计、施工及管理过程中,需要进行水文水利(水能)计算,而水…

-

水文测验实习报告

水文实习报告水文测验实习报告20xx年11月日星期六191水文实习报告目录实验一气象要素观测实验31观测场32百叶箱53气温的测量…

-

水文学实习报告二 文档

水利专业平赴浏阳双江口水文站学实习报告一、目的与要求水利水电工程的规划、设计、施工及管理过程中,需要进行水文水利(水能)计算,而水…

-

20xx年水管处个人述职述廉报告

20xx年度述职述廉报告吴永福20xx年x月转眼瞬间,20xx年即将过去,在这一年中,工作、思想、学习较20xx年都有新的提高,对…

- 水文实习报告

-

水文学实习报告

水文与水资源学实习报告专业班级姓名学号实习地点宜昌水文站三峡大坝实习日期114116指导教师实习成绩1目录引言21实习安排32实习…

-

水文学野外实习报告

地理与资源科学学院地理科学专业20xx级水文野外实习报告实习地点都江堰水文站实习时间20xx072班级20xx级2班学号20xx1…

-

暑期社会实践报告(1)打印

暑期社会实践报告系部名称电气工程学院专业电气工程及其自动化年级20xx班级电气八班姓名刘立鹏学号20xx51574实践单位黑龙江省…