供应链实验报告

《供应链管理》课程实验

供应链仿真实验实验报告

班级____212101_____

姓名__ 刘梦淼______

学号__ 21210103____

一、实验目的

按照供应链管理课程实验大纲的要求,应用仿真软件,对供应链上各节点的参数进行设定,选择不同的需求预测方法以及库存策略,评价供应链的绩效,从而加深对课堂上供应链理论的理解。

通过该实验,学生在实际案例的分析中进一步了解供应链绩效的评价方法,供应链策略的选择对其绩效的影响,供应链上的牛鞭效应。

二、实验方法

本次实验方法主要仿真软件(LOGWARE)来分析供应链的绩效及各节点企业的运作。

三、实验内容

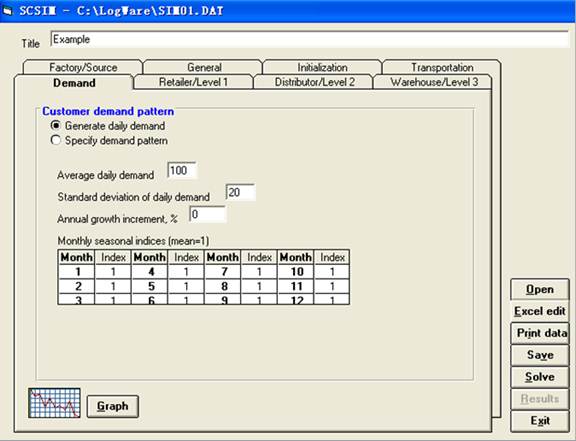

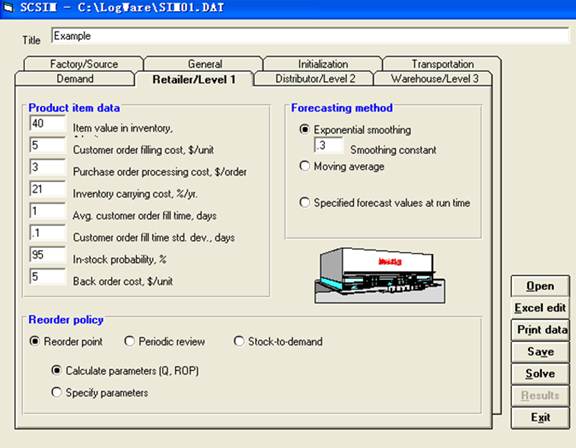

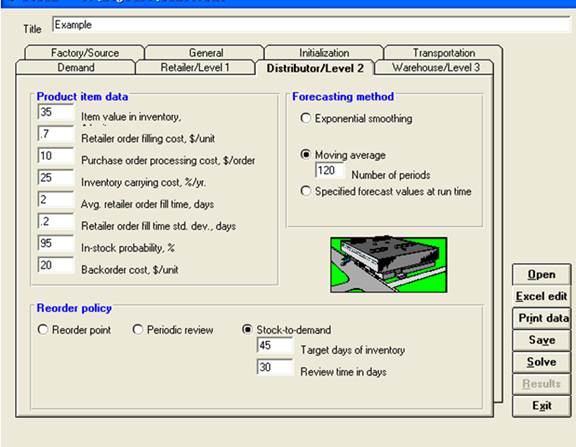

本次实验的内容是熟悉和掌握供应链仿真软件,了解仿真的意义,概率分布类型在仿真中的应用(本仿真中使用正态分布),并且了解不同需求预测模型、订货策略的特点及参数设置方法。本次实验基于计算机仿真,通过一系列假设条件的设置,并运行仿真模型,获得评价供应链绩效的数据,如评估区间内的总收入、总成本、运输费用、定单处理费用、延期交货费用、库存费用、净利润等;对供应链上的各节点,通过需求预测、平均库存量、库存周转率、日订单数量、延期交货订单量等指标,评价其效率,并能通过各节点的订单数据、库存数据比较,进一步理解牛鞭效应理论。

四、实验要求

1.本次实验要求每个同学完成两个案例分析,掌握两个案例中供应链各节点参数的意义及设置方法;比较两个案例的参数设置、需求预测法、订货策略。

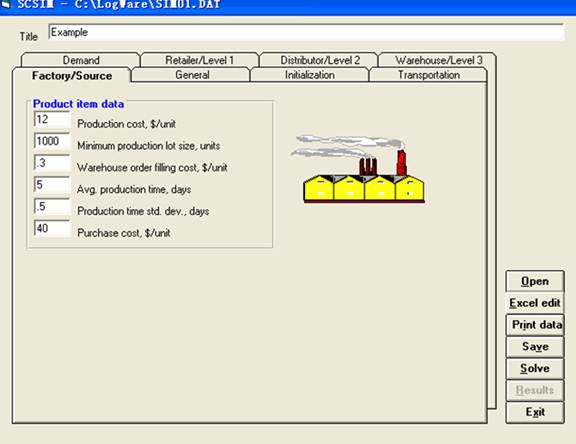

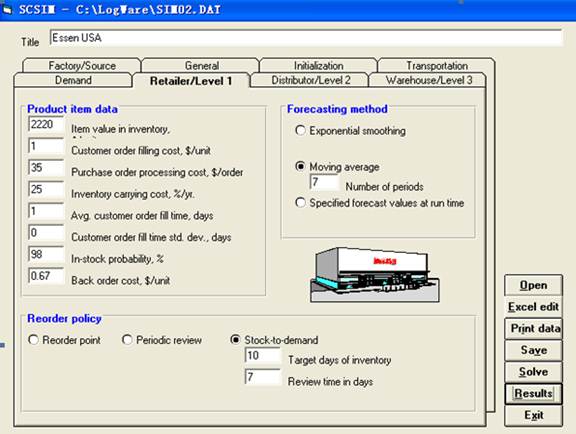

(1)工厂/来源(Factory/Source):(产品项目资料)产品费用、规格、仓库费用、平均生产时间、购买费用等;

(2)需求设置(Demand):顾客需求模型包括:一般日常需求和特定需求模式;有日平均需求、日需求标准偏差、年平均增长率以及一年12个月指标;

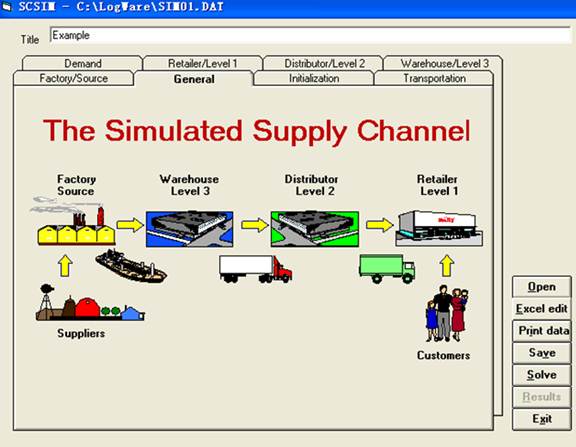

(3)一般设置(General):从供应者、工厂、仓库、配送商、零售商最后至顾客手中的全过程;

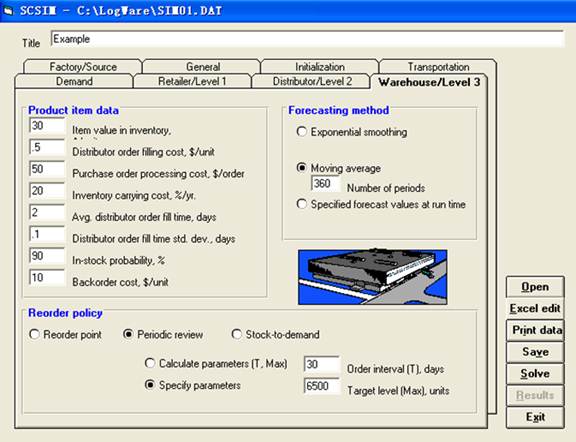

(4)零售商/第一级设置(Retailer Level 1):1)产品项目资料:库存价值、合理订单成本、库存履行水平、从供应者、工厂、仓库、配送商、零售商最后至顾客手中的全过程;2)预测方法:指数平滑法、移动平均法、在一定期间特定的预测值;3)再订购策略:按点再订购、按期间再订购、按库存需求再订购;

(5)初始值设置(Initialization):种子值、仿真模拟时间、每千磅销售价格;

(6)零售商仓库/第二级设置(Retailer Level 2):具体内容与零售商/第一级设置内容相同;

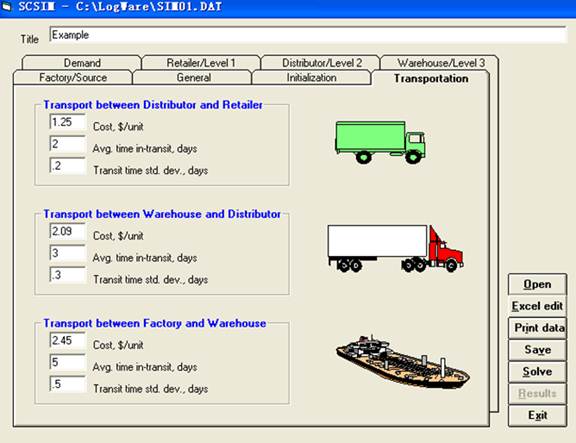

(7)运输设置(Distributor):零售商仓库到零售商参数设置(运输费用、平均运输时间、标准差);仓库到零售商仓库参数设置(运输费用、平均运输时间、标准差);工厂到仓库参数设置(运输费用、平均运输时间、标准差);

(8)仓库/第三级设置(Warehouse Level 3):具体内容与零售商/第一级设置内容相同。

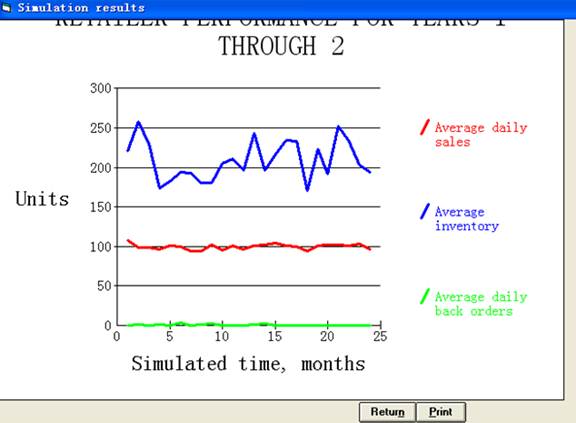

2.理解仿真结果报告(Simulation Results)中包含的信息。通过对报告的分析,了解供应链绩效评价指标和方法。

SUPPLY CHANNEL REPORT FOR SIMULATED YEARS 1 TO 2(1-2年的供应渠道模拟报告)

Yearly Simulated

Average(年平均) period(模拟期) FINANCIAL PERFORMANCE(财务绩效)

$2,692,163 $5,384,325 Revenue(收入)

1,420,000 2,840,000 Cost of purchased goods(采购商品成本)

1,272,163 2,544,325 Gross margin(毛利)

426,000 852,000 Production cost(生产成本)

Transportation costs: (运输成本)

44,866 89,731 Distributor to retail(分销商到零售商)

75,319 150,639 Warehouse to distributor(仓库到分销商)

86,975 173,950 Factory to warehouse(工厂到仓库)

Sales order handling cost for:(销售订单处理成本)

179,478 358,955 Customer orders(客户订单)

25,119 50,238 Retailer orders(零售商的订单)

18,019 36,038 Distributor orders(经销商的订单)

Order processing cost for:( 订单处理成本)

666 1,332 Orders to distributor(经销商订单)

120 240 Orders to warehouses(仓库订单)

600 1,200 Orders to factory(工厂订单)

Inventory costs(库存成本)

1,756 3,512 Retailer(零售商)

22,975 45,951 Distributor(经销商)

13,056 26,112 Warehouse(仓库)

Back order costs(延迟订单成本)

955 1,910 Retailer(零售商)

0 0 Distributor(经销商)

23,645 47,290 Warehouse(仓库)

$352,613 $705,227 Net profit contribution(净利润的贡献)

DISTRIBUTOR REPORT FOR SIMULATED YEARS 1 TO 2(1-2年的经销售模拟报告)

Forecasting method: Moving average(预测方法:移动平均法)

Inventory control method: Stock-to-demand(库存控制方法:库存需求)

Yearly Simulated

Average(年平均) period(模拟期) PERFORMANCE STATISTICS(性能统计)

36,165 72,329 Sales Forecast, units(销售预测)

36,437 72,874 Distributor sales to retailer, units

(仓库销售到经销商)

2,417.10 Average inventory on hand, units(平均库存)

15.07 Inventory turnover ratio(库存营业额)

411 Daily back orders, units(日延期订单)

<50% Average demand filled on request

(平均需求)

6,283 12,565 Back order occurrences(延期订单)

2,049 Daily quantity on order, units(日常订单数量)

9 18 Number of orders placed(订单数目)

FINANCIAL PERFORMANCE(财务绩效)

675.00 1,350 Cost to process warehouse orders

(仓库处理订单的成本)

728,740.00 1,457,480 Cost for handling retailer orders

(零售商处理订单的成本)

1,341,488.19 2,682,976 Cost for carrying inventory(搬运)

628,250.00 1,256,500 Cost for back orders(延期交货成本)

997,600.00 1,995,200 Cost for transport to retailer

(到零售商的运输成本)

$3,696,753.19 $7,393,506 Total cost(总成本)

WAREHOUSE REPORT FOR SIMULATED YEARS 1 TO 2(1-2年的仓库模拟报告)

Forecasting method: Moving average(预测方法:移动平均法)

Inventory control method: Periodic review(库存控制方法:定期审查)

Yearly Simulated

Average(年平均) period(模拟期) PERFORMANCE STATISTICS(性能统计)

36,768 73,536 Sales Forecast, units(销售预测)

36,038 72,076 Warehouse sales to distributor, units(仓库销售到经销商)

2,176.01 Average inventory on hand, units(平均库存)

16.56 Inventory turnover ratio(库存营业额)

49.76 Daily back orders, units(日延期订单)

50.29% Average demand filled on request

(平均需求)

2,364.50 4,729 Back order occurrences(延期订单)

1,508 Daily quantity on order, units(日常订单数量)

12 24 Number of orders placed(订单数)

FINANCIAL PERFORMANCE(财务绩效)

600.00 1,200 Cost to process factory orders

(工厂处理订单的成本)

18,019.00 36,038 Cost for handling distributor orders

(经销商处理订单的成本)

13,056.04 26,112 Cost for carrying inventory(搬运)

23,645.00 47,290 Cost for back orders(延期交货成本)

75,319.42 150,639 Cost for transport to distributor(到经销商的运输成本)

$130,639.46 $261,279 Total cost(总成本)

FACTORY REPORT FOR SIMULATED YEARS 1 TO 2(1-2年的工厂模拟报告)

Yearly Simulated

Average(年平均) period(模拟期) PERFORMANCE STATISTICS(性能统计) 35,500 71,000 Factory sales to warehouse, units

FINANCIAL PERFORMANCE(财务绩效)

1,420,000.00 2,840,000 Cost of purchased materials(原料成本)

426,000.00 852,000 Cost of production(生产成本)

86,975.00 173,950 Cost for transport to warehouse

(工厂到仓库的运输成本)

$1,932,975.00 $3,865,950 Total cost(总成本)

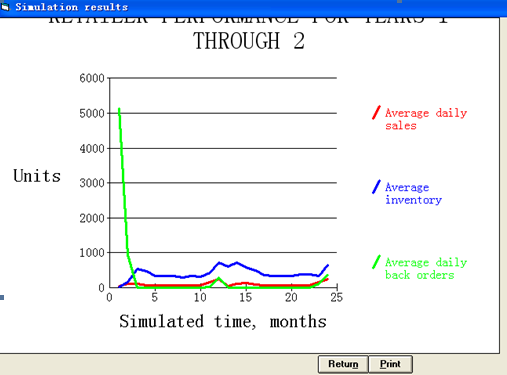

3、通过运行仿真程序,对供应链上各节的订单数据、库存数据进行比较,证明牛鞭效应理论。

“牛鞭效应”是市场营销中普遍存在的高风险现象,是销售商与供应商在需求预测修正、订货批量决策、价格波动、短缺博弈、库存责任失衡和应付环境变异等方面博弈的结果,增大了供应商的生产、供应、库存管理和市场营销的不稳定性。

SUPPLY CHANNEL REPORT FOR SIMULATED YEARS 1 TO 2

Yearly Simulated

average period FINANCIAL PERFORMANCE

$104,907,000 $209,814,000 Revenue

40,505,000 81,010,000 Cost of purchased goods

64,402,000 128,804,000 Gross margin

34,429,250 68,858,500 Production cost

Transportation costs:

997,600 1,995,200 Distributor to retailer

2,793,280 5,586,560 Warehouse to distributor

3,159,390 6,318,780 Factory to warehouse

Sales order handling cost for:

36,300 72,600 Customer orders

728,740 1,457,480 Retailer orders

534,495 1,068,990 Distributor orders

Order processing cost for:

1,645 3,290 Orders to distributor

675 1,350 Orders to warehouses

638 1,275 Orders to factory

Inventory costs

225,804 451,608 Retailer

1,341,488 2,682,976 Distributor

1,956,443 3,912,887 Warehouse

Back order costs

3,346 6,692 Retailer

628,250 1,256,500 Distributor

322,075 644,150 Warehouse

$17,242,581 $34,485,162 Net profit contribution

DISTRIBUTOR REPORT FOR SIMULATED YEARS 1 TO 2

Forecasting method: Moving average

Inventory control method: Stock-to-demand

Yearly Simulated

average period PERFORMANCE STATISTICS

36,165 72,329 Sales Forecast, units

36,437 72,874 Distributor sales to retailer, units

2,417.10 Average inventory on hand, units

15.07 Inventory turnover ratio

411 Daily back orders, units

<50% Average demand filled on request

6,283 12,565 Back order occurrences

2,049 Daily quantity on order, units

9 18 Number of orders placed

FINANCIAL PERFORMANCE

675.00 1,350 Cost to process warehouse orders

728,740.00 1,457,480 Cost for handling retailer orders

1,341,488.19 2,682,976 Cost for carrying inventory

628,250.00 1,256,500 Cost for back orders

997,600.00 1,995,200 Cost for transport to retailer

$3,696,753.19 $7,393,506 Total cost

WAREHOUSE REPORT FOR SIMULATED YEARS 1 TO 2

Forecasting method: Moving average

Inventory control method: Stock-to-demand

Yearly Simulated

average period PERFORMANCE STATISTICS

36,833 73,665 Sales Forecast, units

35,633 71,266 Warehouse sales to distributor, units

5,720.59 Average inventory on hand, units

6.23 Inventory turnover ratio

1,315.52 Daily back orders, units

<50% Average demand on request

12,883.00 25,766 Back order occurrences

1,931 Daily quantity on order, units

9 17 Number of orders placed

FINANCIAL PERFORMANCE

637.50 1,275 Cost to process factory orders

534,495.00 1,068,990 Cost for handling distributor orders

1,956,443.30 3,912,887 Cost for carrying inventory

322,075.00 644,150 Cost for back orders

2,793,280.00 5,586,560 Cost for transport to distributor

$5,606,930.80 $11,213,862 Total cost

FACTORY REPORT FOR SIMULATED YEARS 1 TO 2

Yearly Simulated

average period PERFORMANCE STATISTICS

40,505 81,010 Factory sales to warehouse, units

FINANCIAL PERFORMANCE

40,505,000.00 81,010,000 Cost of purchased materials

34,429,250.00 68,858,500 Cost of production

3,159,390.00 6,318,780 Cost for transport to warehouse

$78,093,640.00 $156,187,280 T otal cost

五、思考题

1. 什么叫计算机仿真(Computer simulation)?在供应链及物流系统分析及优化中应用仿真分析法,其优势有哪些?

答:计算机仿真(computer simulation)利用计算机科学和技术的成果建立被仿真的系统的模型,并在某些实验条件下对模型进行动态实验的一门综合性技术。它具有高效、安全、受环境条件的约束较少、可改变时间比例尺等优点,已成为分析、设计、运行、评价、培训系统(尤其是复杂系统)的重要工具。

在供应链及物流系统分析及优化中应用仿真分析法,其优势有:

(1)并行运算,速度快,很方便;通过软件仿真可以很快解决实际供应链上的决策选址、路线和预测等。

(2)很实用,输出为连续量,易于与实物连接,更接近实际的控制系统,与实际供应链模型较为吻合;

2. SCSIM对供应链做了哪些假设和简化,这种假设和简化是否合理?除了系统模块中已涉及的因素和条件外,您认为程序还可以做哪些改进?

答:假设和简化:所有的分布是正常的1的最小平均值;在一个正常的分布产生一个小于1的数字被截断为1;时间规定是一天,一周7天,一个月30天,一年360天;到达某一天一个梯队通道添加量从之前由于销售库存扣除库存了;销售需求和生产批量的最小值大小是1;产品批量是整数;数字输入数据或计算的值大于1000000000,应尽量避免他们可能导致溢出错误;所有制成为病命令返回的订单,不失去销售,直到足够的库存,可以消除回订单。这些假设和简化还是比较合理的。

改进:增加一些因子,如增加供应商、工厂、经销商、零售商的个数等。

六、实验小结

LOGWARE是一款集选择、分析的软件程序,用于物流和供应链管理的相关问题和案例研究。本实验主要应用LOGWARE中的SCSIM模块,SCSIM模块主要是对一个供应渠道进行仿真预测。

通过四节课的上机实验操作,我们对LOGWARE软件有了进一步的了解。SCSCIM模块仿真模拟操作可以帮助我们较快地解决供应链上的决策预测模型,通过正态分布、指数平滑法、移动平均法等较为准确地预测。仿真目的是模拟和仿真性能和供应渠道成本时,各种预测方法研究,库存政策,运输服务,生产批量,订单处理成本等用于整个供应通道。用报告和图形来描述供应链执行不同的机会模拟运行。

-

供应链管理实验报告

福建工程学院实验名称实验报告物流实验专业班级会计学1005班姓名学号3101503408(9号)指导教师傅成红日期20xx-12-…

-

供应链实验报告

序号17云南师范大学商学院实验报告册学期20xx20xx学年下学期课程名称财务软件应用实验名称财务软件应用综合实验班级学号姓名20…

-

供应链实验报告

供应链管理课程实验供应链仿真实验实验报告班级212101姓名刘梦淼学号21210103一实验目的按照供应链管理课程实验大纲的要求应…

-

供应链管理实验报告

供应链管理实验一、实验目的:通过实验能够根据物流供应链管理理论,在金蝶K3软件进行供应链管理模拟,从而体会企业进行物流供应链管理的…

-

供应链管理实验报告

昆明理工大学实验报告用友ERP实验学号姓名年级学院系别专业实验日期20xx年3月11日至20xx年6月10日报告日期20xx年6月…

-

物流供应链软件实训实习报告

物流软件实训实习总结报告我们物流专业的同学在学校为期两个星期的物流软件实训。在这里,我们锻炼了两个星期,或多或少的对物流的业务在软…

-

供应链管理 实训1

实训报告3、①益海嘉里细化供应链管理重点在于做好企业的财务监控,从粮油生产收购到生产再到运输的诸多环节,不仅在生产工艺上要求严格,…

-

供应链管理实验报告

福建工程学院实验名称实验报告物流实验专业班级会计学1005班姓名学号3101503408(9号)指导教师傅成红日期20xx-12-…

-

供应链管理实训报告

实训专业:物流管理实训班级:物流1011实训地点:校内(教室、实训中心),校外(各物流企业)指导老师:周慧实训目的:在学期末,为了…

-

供应链管理实训报告

供应链管理实训报告姓名----李绍盛班级----11级物流学号----20xx032133学院----宁德职业技术学院指导老师--…

-

物流采购与供应链管理实训报告

物流采购与供应链管理实训报告实训专业:物流管理实训地点:校内(教室、实训中心),新校区实训目的:在学期末,为了更好的让我们了解社会…